An Order BOM helps engineers and manufacturing teams to order parts and perform initial production planning. Initial production planning involves creating a planning BOM (order BOM) to manage the right quantities and coordinate the ordering process internally in a company and externally with contractors and suppliers.

Background

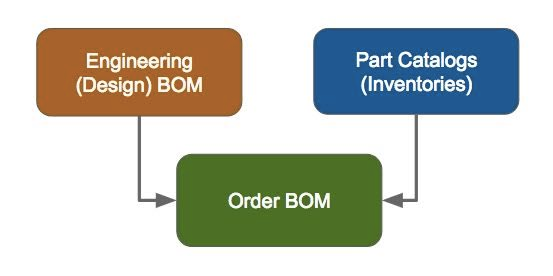

There are two sources of input data required to create an order BOM: (1) engineering (or design BOM) and (2) Part catalogs (inventories). The engineering (design) BOM contains all the parts designed and engineered in the product. In OpenBOM this BOM usually comes from a variety of CAD integrations, any number of Excel sources imported to OpenBOM, and manual data input. A part catalogs (or inventories) in OpenBOM is a list of all the parts in a company, both engineering and standard parts.

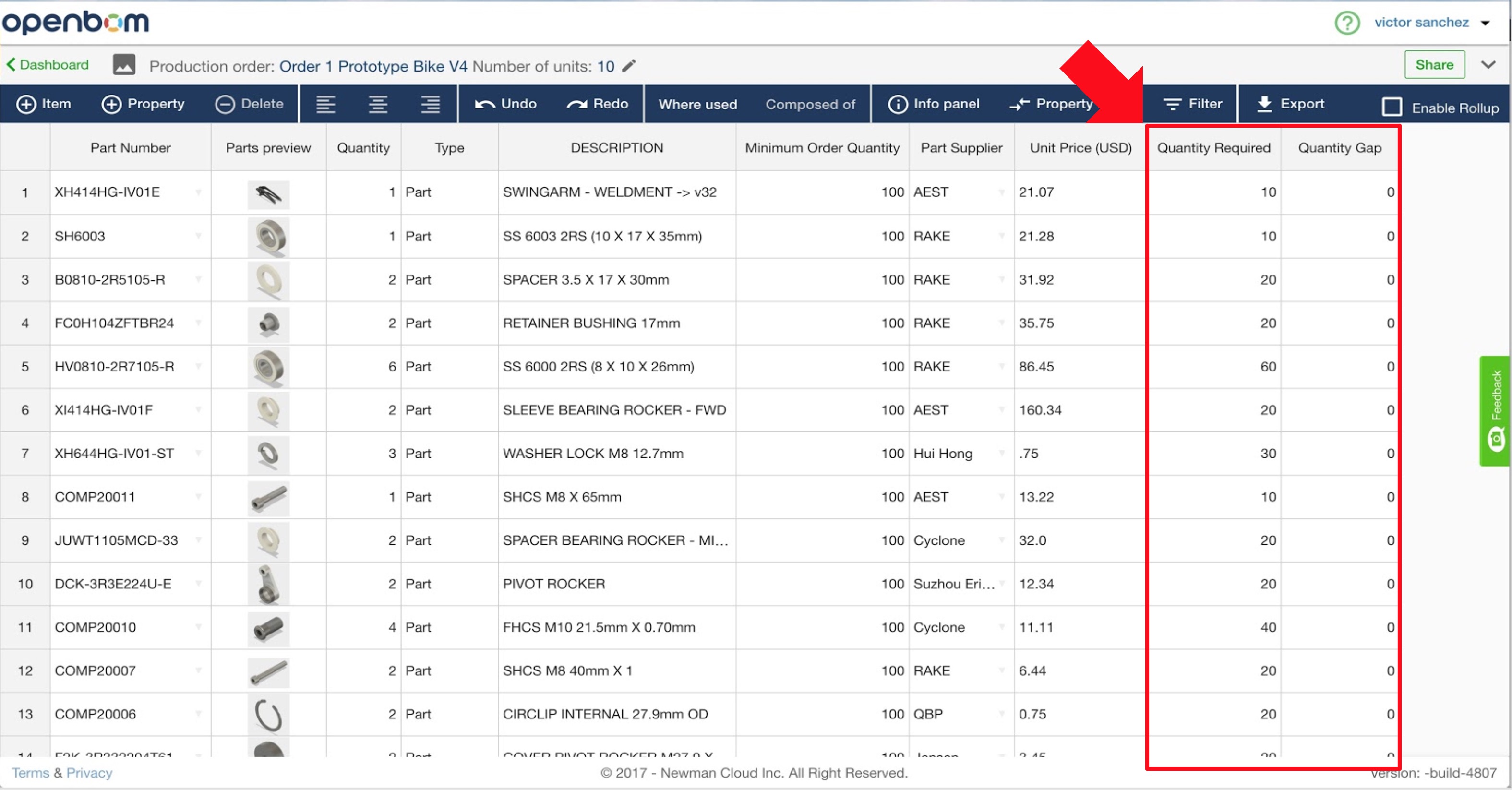

The Order BOM definition contains both the number of product units and a list of parts to be ordered as well as the required quantities of parts and quantities gaps. The number of units, Quantity required, is defined when a production batch for a released BOM is created in OpenBOM. Quantity gap is calculated based on the part quantity as defined in the part catalogs (inventory).

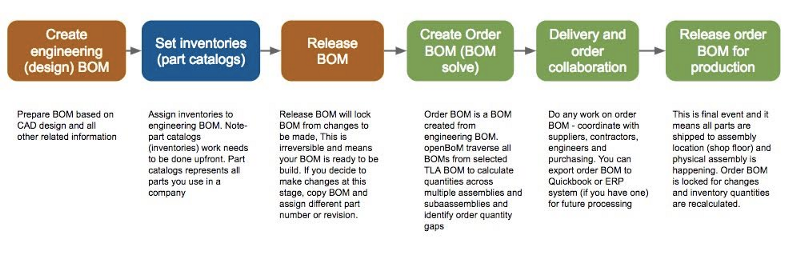

Here’s the flow as it currently works in OpenBOM:

Steps for creating an Order BOM (video below)

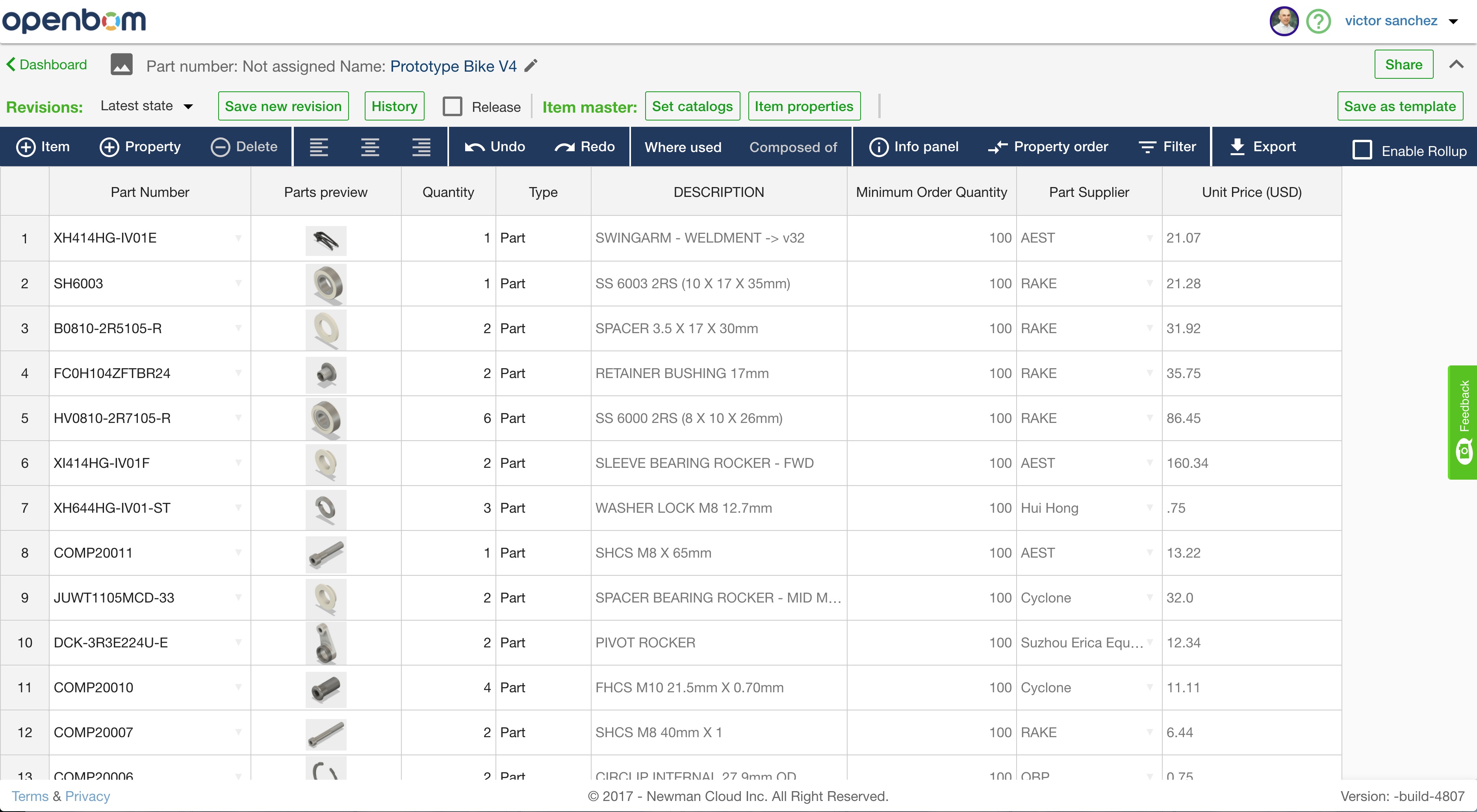

(1) Create engineering (design) BOM. Note: Your BOM must contain a “Quantity” property. For the purposes of creating an Order BOM, all other quantity properties and their values, e.g. Factory Stock, in a BOM will be ignored.

Here’s a pic of a BOM in OpenBOM ready for release:

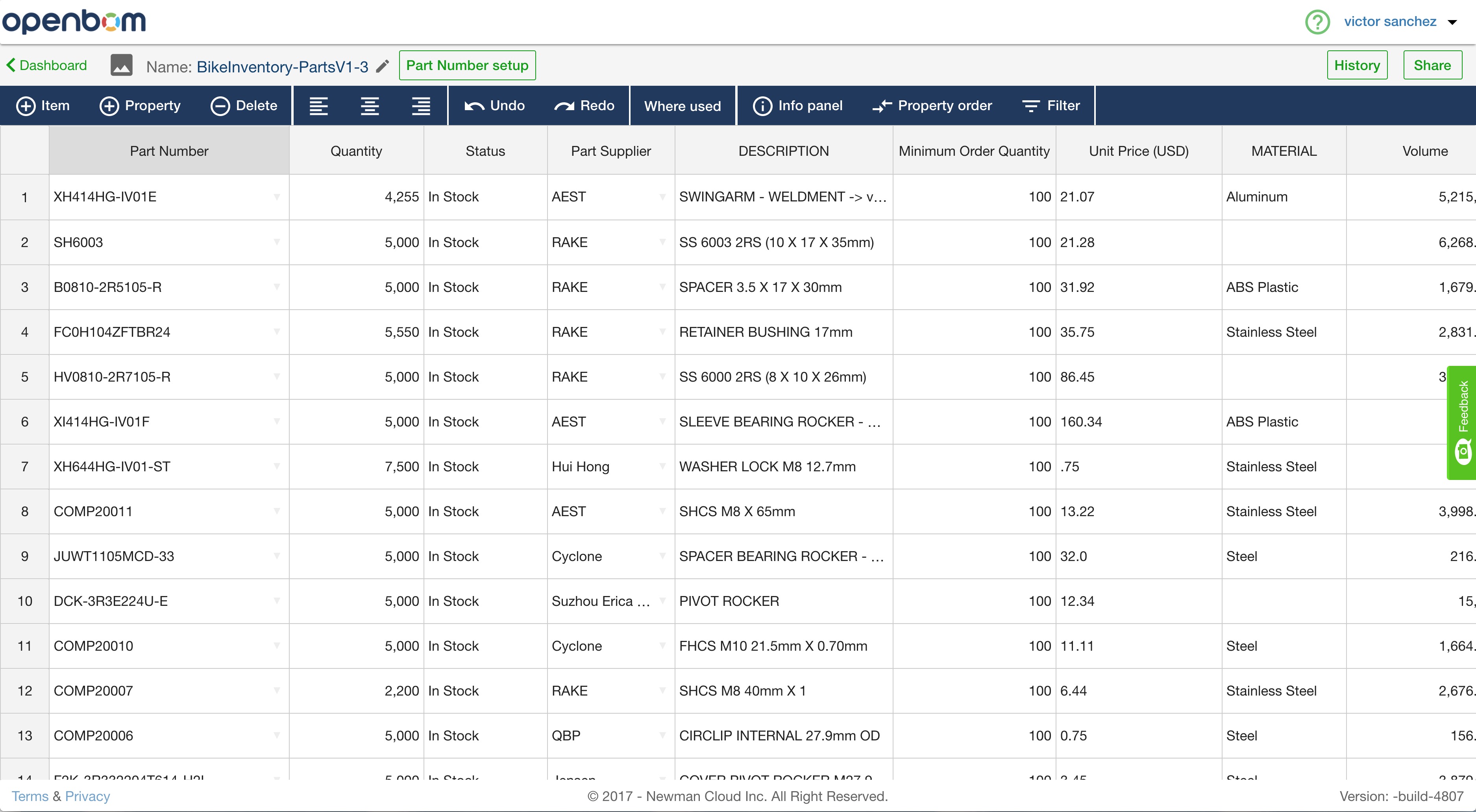

(2) Set inventories (part catalogs). Assign inventories to the engineering BOM. Note: Make sure your part catalog (inventory) contains a ‘Quantity” property with the available number of parts in your organization. Even if your BOM contains

Here’s a pic of a part catalog (inventory) assigned to the engineering BOM. Learn how to assign a part catalog (inventory) to a BOM, here.

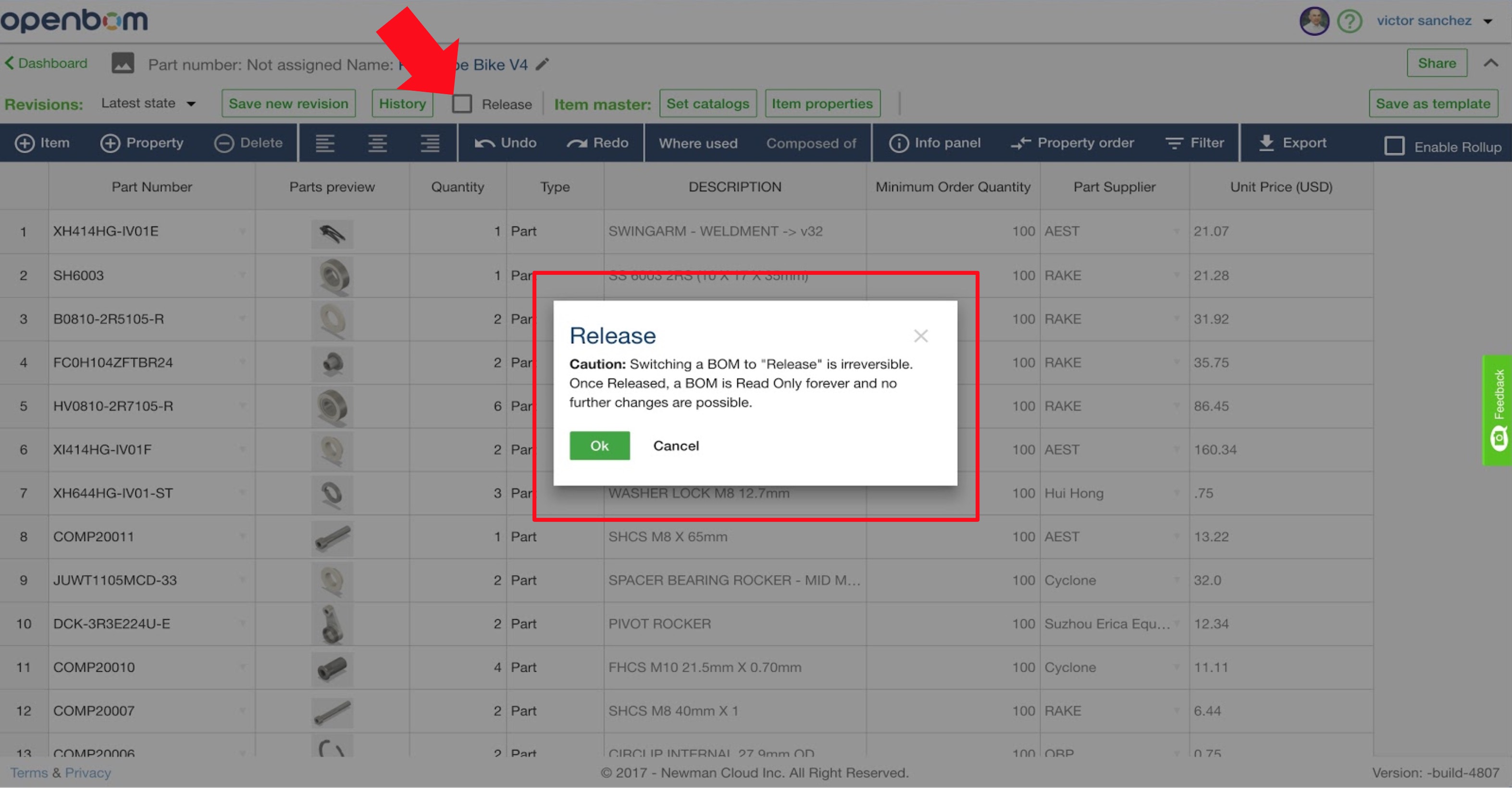

(3) Release BOM. Click the “Release” box to release a BOM:

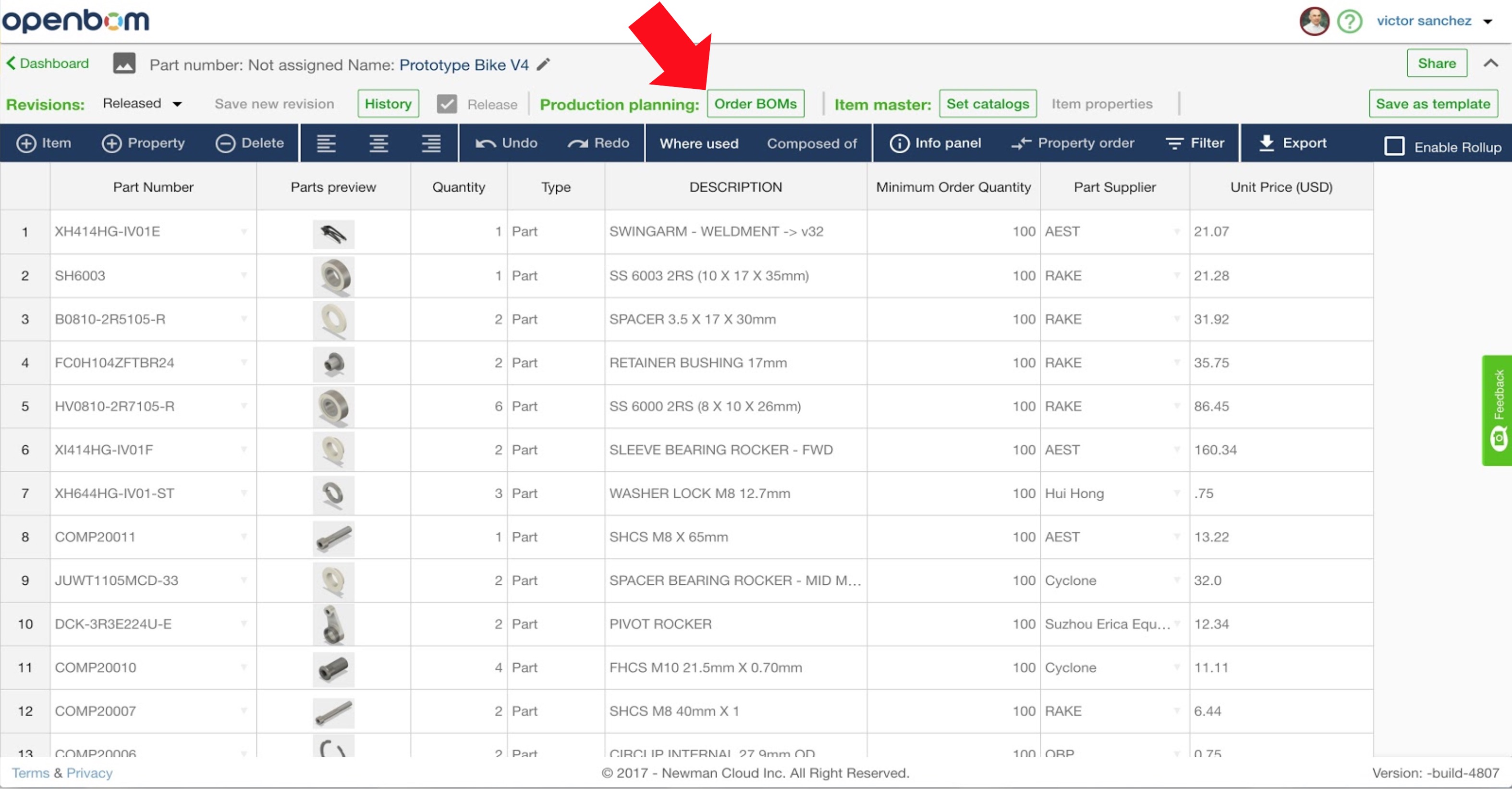

Note: Release BOM will lock BOM from further changes. Make sure to make a copy of the BOM with a different version number before it is released if there is any doubt. Here’s what a BOM looks like after it’s been released:

(4) To create an Order BOM (BOM Solve), a few steps are involved after you have released the BOM:

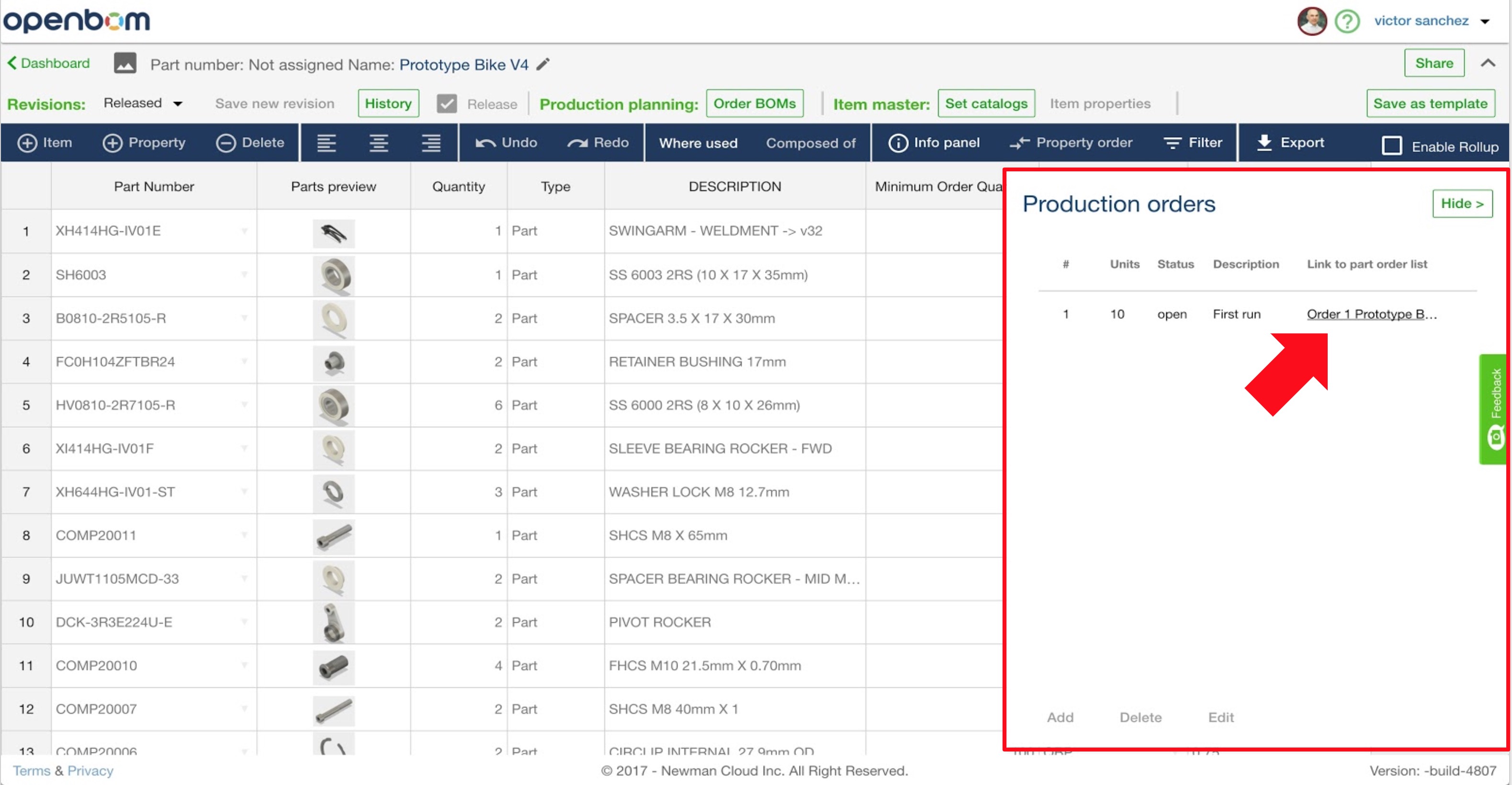

Step 1: A “Production Planning:” label will appear. Click the “Order BOM” button next to it.

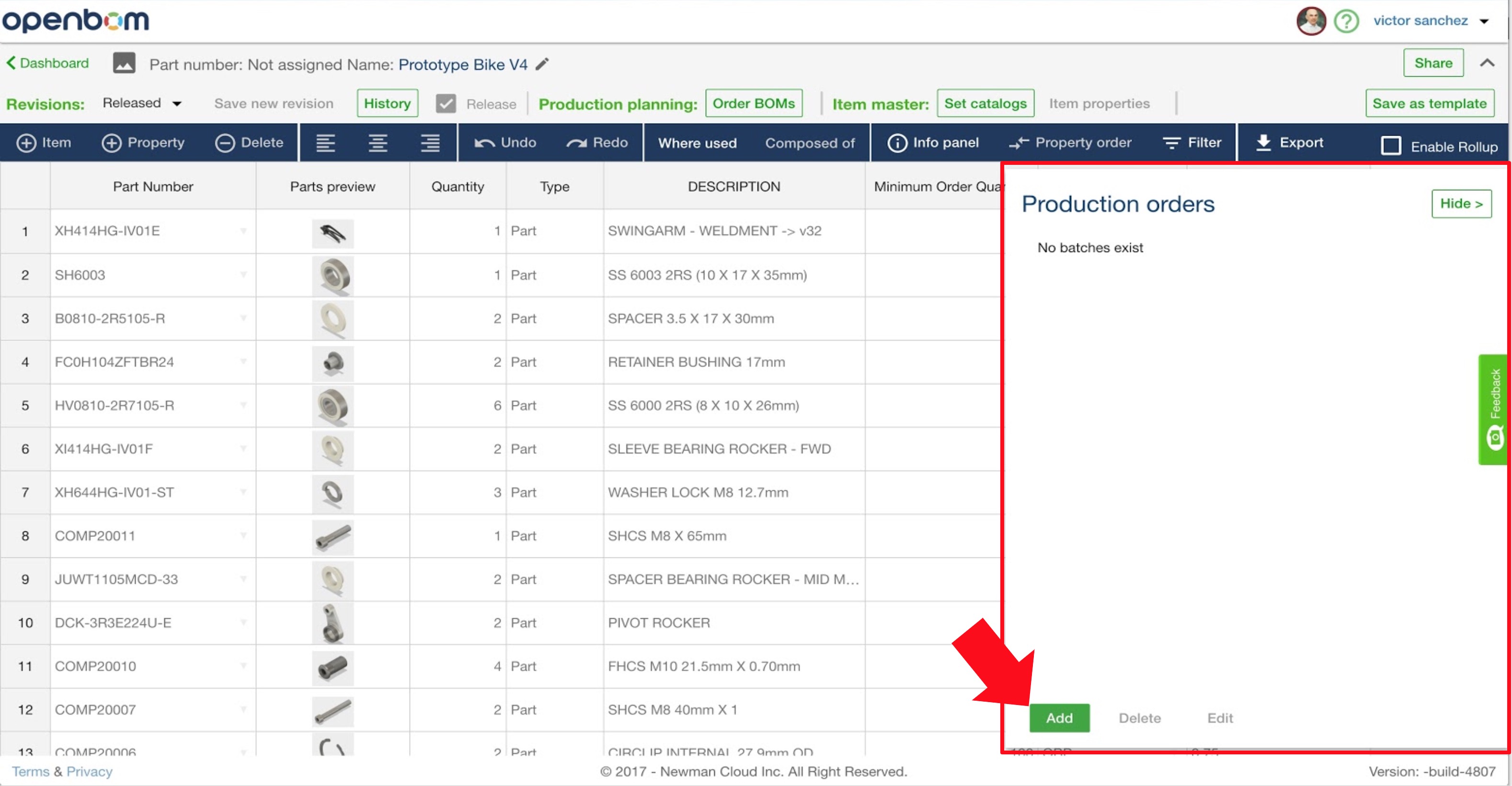

Step 2: Click the “Add” button in the Production orders window that appears after clicking “Order BOM”.

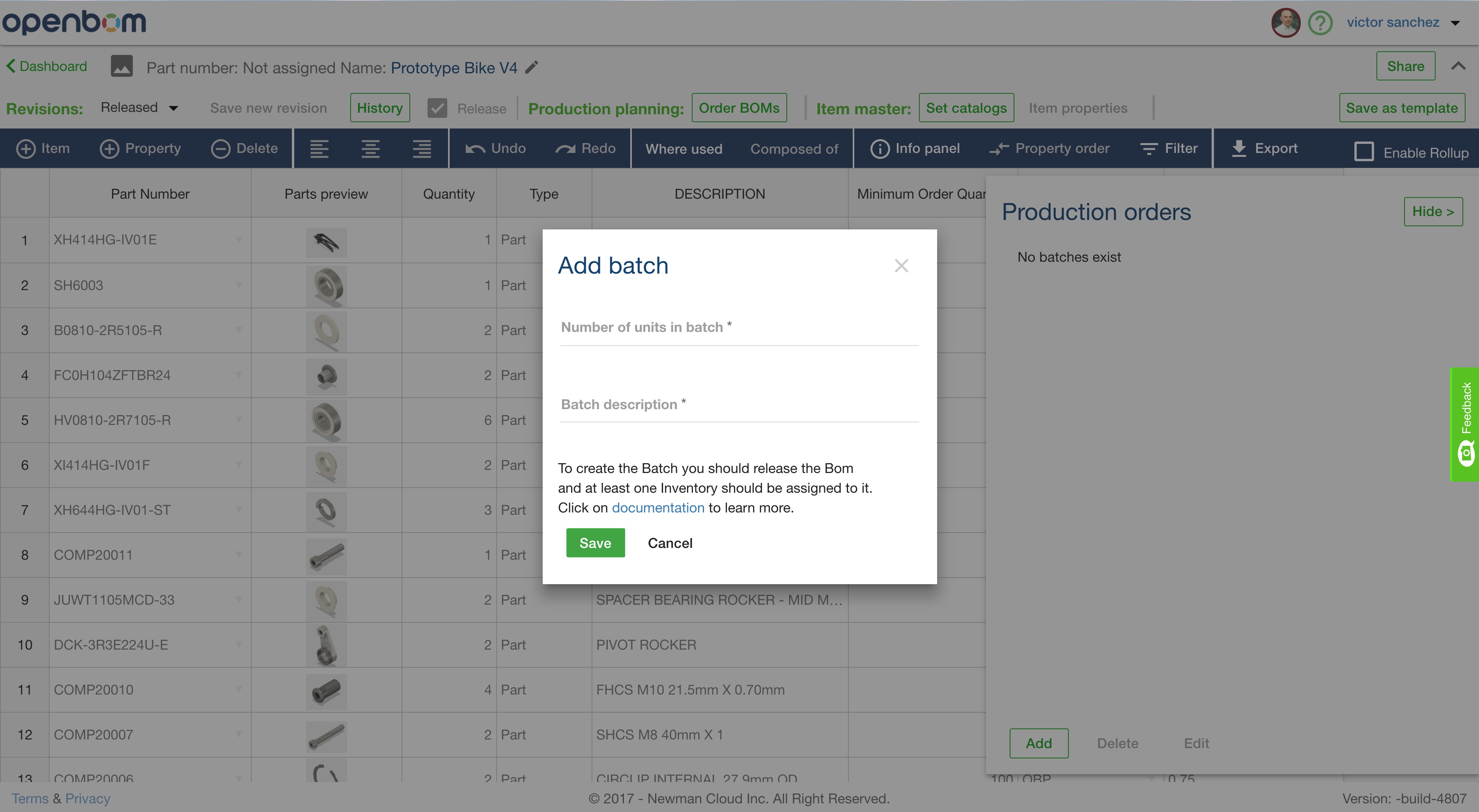

Step 3: Add batch information in the modal window, unit count to produce and the name or short description of the batch. Make sure to click “Save“.

Step 4: Access the Order BOM by clicking the link of the production order:

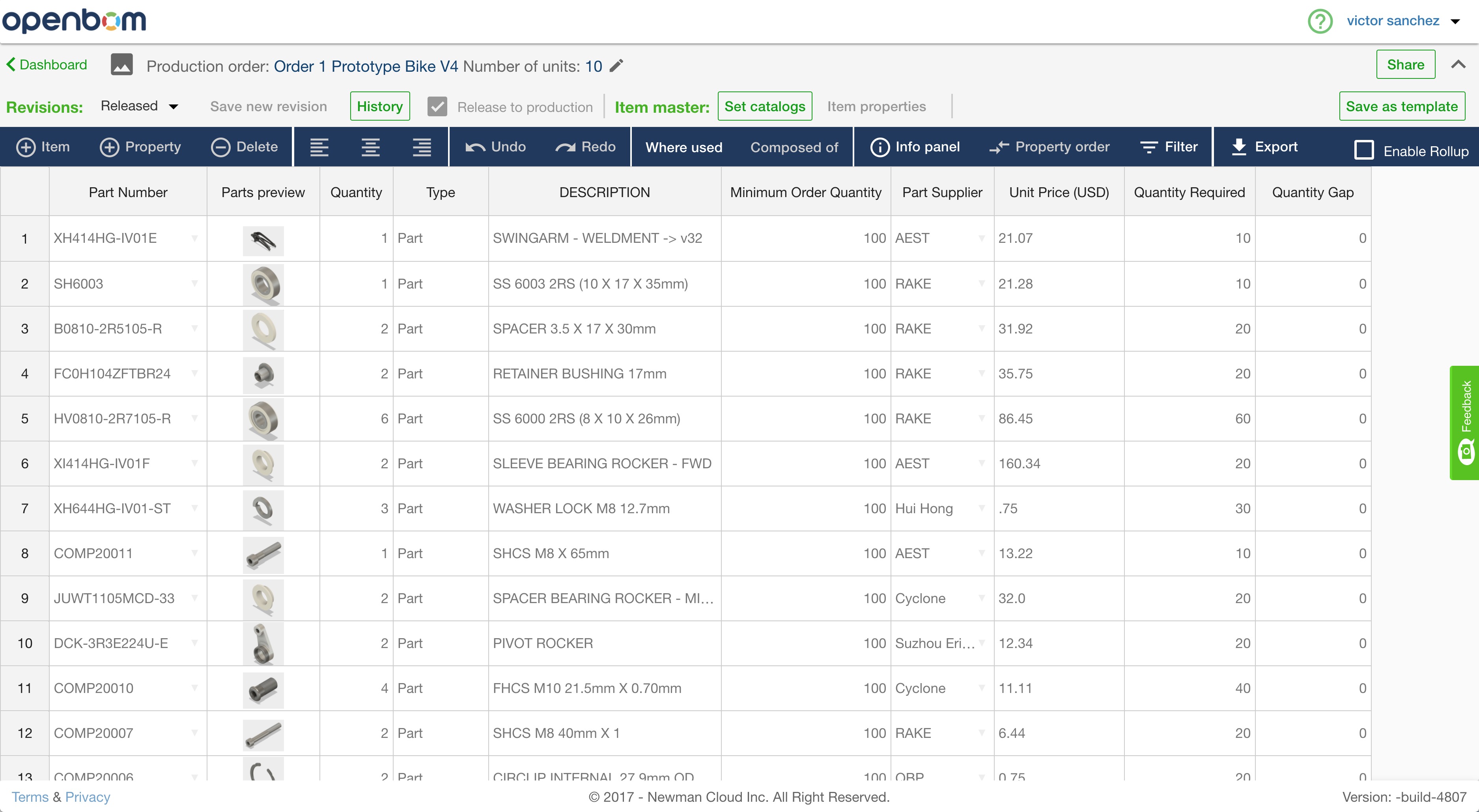

Here’s a pic of the Order BOM. Notice how Quantity Required and Quantity Gap are included.

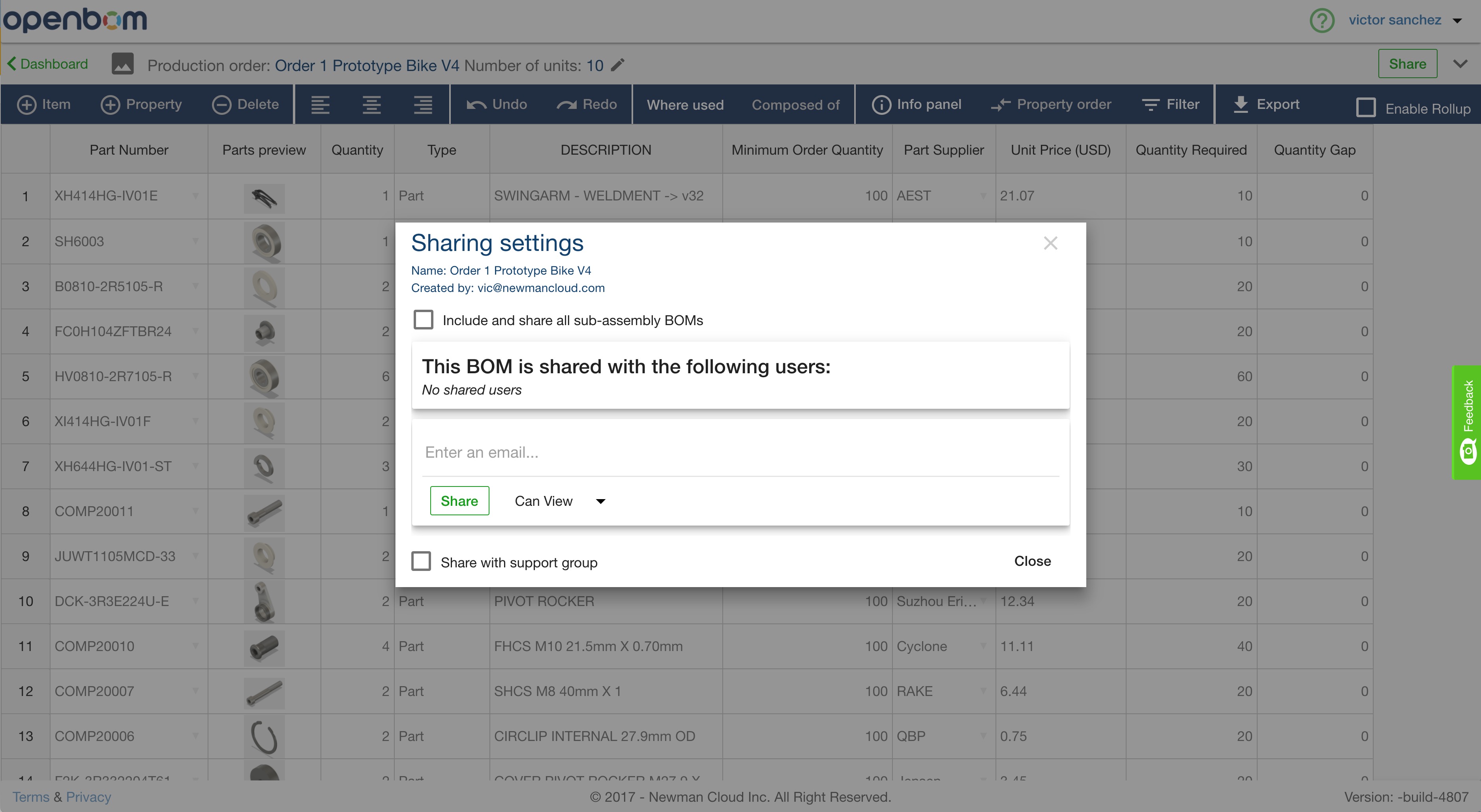

(5) Delivery and order collaboration. You can share the Order BOM with others and invite them to coordinate the final order (before releasing to production). At this stage, changes are allowed to the Order BOM.

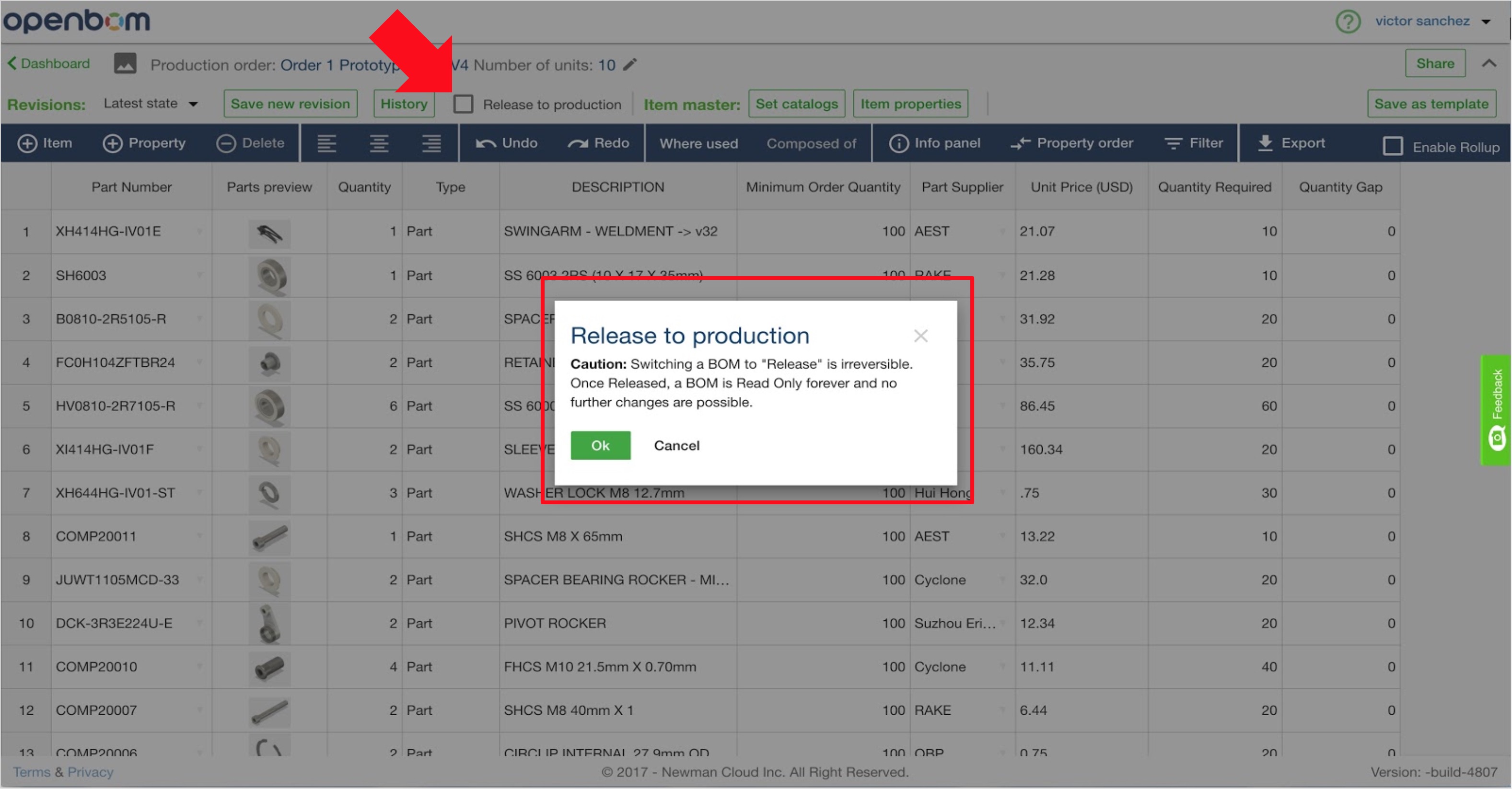

(6) Release order BOM for production. When the Order BOM is ready for release, click “Release to production” box.

Here’s what a release to production Order BOM looks like: Note: This step is final for this particular batch. The Order BOM is locked (changes can no longer be made) and part catalogs (inventory) quantities are re-calculated.

IMPORTANT! Please note:

- In the current implementation of Order BOM, only one batch (i.e. Order BOM) can be opened, meaning you cannot create a new batch (i.e. Order BOM) without releasing it (see step 6, above) or deleting a previously created batch (i.e. Order BOM).

- You can add a new batch and delete it as many times as you wish, but only after the batch has been released to production (step 6, above) can you create another batch.

- When a batch is released to production, inventory quantities will be recalculated. Afterwards, however, if you change the quantity in the inventory, it will impact only the next batch you create. Existing batches (i.e. created before any change to inventory) will not be impacted.

- An Inventory assigned to different BOMs or shared with different people is not protected when used to create multiple production batches from those BOMs. The current release, quantity inconsistencies may occur. A fix will be implemented in the next product release.

Here’s a video showing you how the aforementioned six steps come together to create an Order BOM: