If you’re new to OpenBOM, we recommend you watch these videos. They’ll give you an overview of how to get started using OpenBOM. More videos are available on your YouTube channel, here.

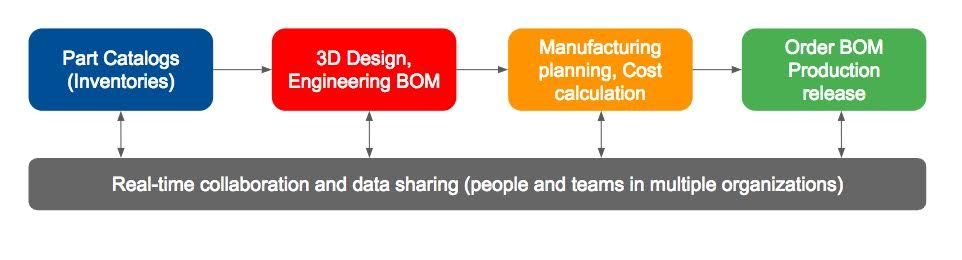

Before we get started, let’s first set the stage. OpenBOM first and foremost is a data management system for engineering, manufacturing, and supply chain. At the heart of all manufacturing processes, there is a Bill of Materials. If the BOM is the heart, then data is the blood pumping throughout the manufacturing process. For example, in many manufacturing shops, data flow looks like this:

At a high-level, manufacturing data follows this generic path:

- Part Catalogs are created for engineering and standard components;

- Engineering BOMs are generated from CAD systems;

- The BOMs are used for manufacturing planning, cost estimation, catalog visibility; and finally

- An Order BOM is generated and used for production release.

OpenBOM can be used for all the aforementioned items. Getting started with OpenBOM, however, involves just item (1) and (2), above. Because OpenBOM is flexible and adapts to how you work, the actual order isn’t important, i.e., you can either first create a Part Catalog or a BOM.

As a new user getting started with OpenBOM for the first time, what is important is creating your first BOM (or Part Catalog) using your preferred data source, .e.g, from a spreadsheet, from a CAD system, or in some cases, created from scratch. With this in mind, let’s get started.

Managing Parts and Bills of Materials

Importing and exporting data to and from OpenBOM

Real-time collaboration in OpenBOM

Integration with Cloud Systems

https://www.youtube.com/watch?v=VUnbmAkf68c

Small batch manufacturing planning

Integration with desktop CAD and exporting data to PLM and ERP systems