Managing Part Numbers is not a simple (or easy) topic; it’s easy to get them and yourself confused. For example, Who should assign Part Numbers? Which Part Numbers should be used? Can we use manufacturer and supplier’s part numbers? Should we create our own part numbering schemes? These are valid questions and as an engineer that is part of a hardware team or in a larger manufacturing company, you will have to decide what to do. There is no single recipe or simple answers.

I will describe three strategies OpenBOM uses to help manage Part Numbers in hardware and manufacturing organizations. The range of Part Number sources can be large and varied. Using externally defined part numbers, for example, from a McMaster and Octopart catalog could be useful. Part Numbers can be used as references to purchased parts which manage records for each Item (Part) in your product, team or organization. Let’s now have a look at how OpenBOM gives flexibility managing Part Numbers.

- Part list with property referencing Part Number of purchased part

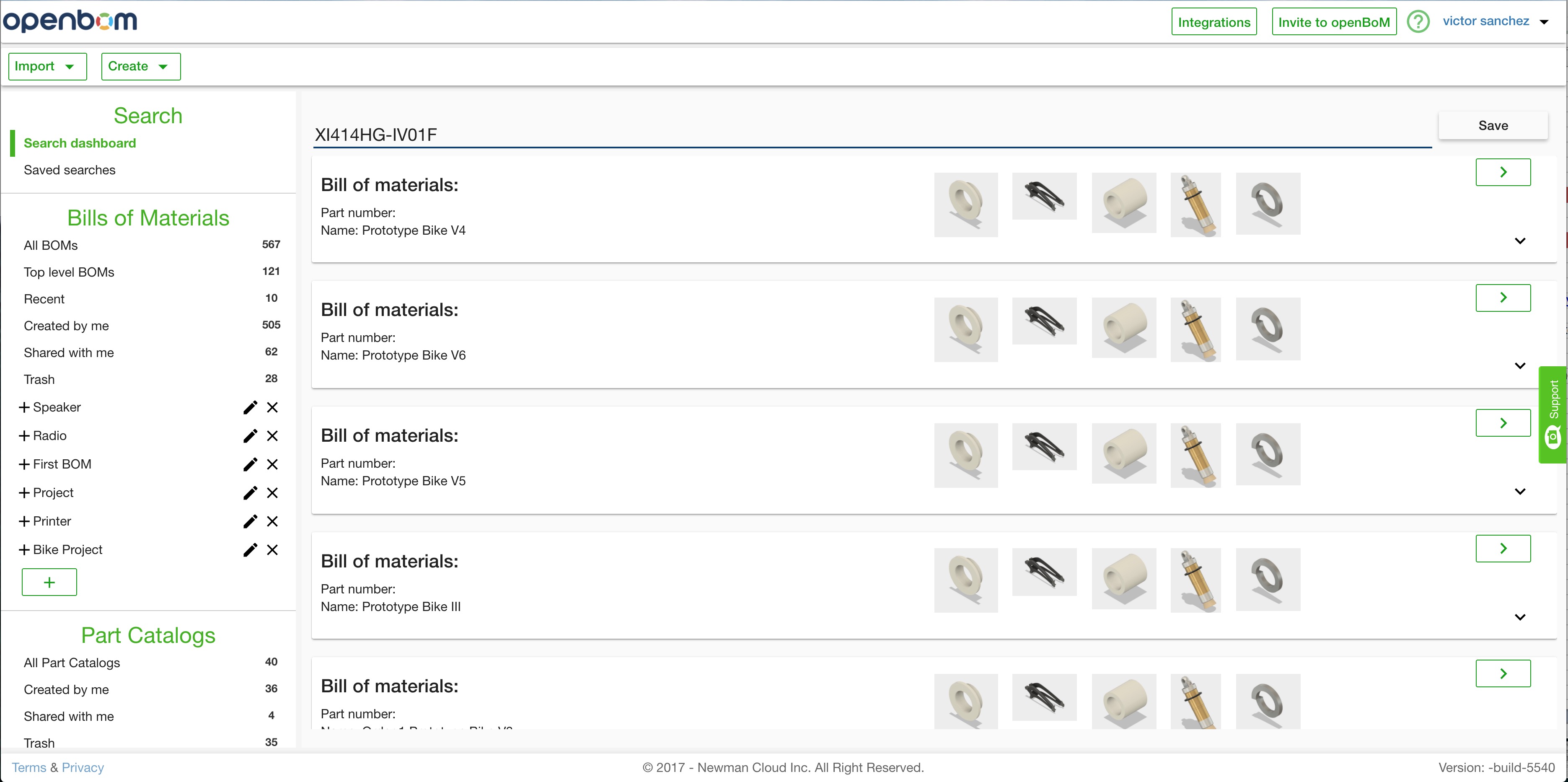

This is one of the easiest ways to deploy Part Numbers in a BOM. You add a reference property in OpenBOM that links to a Part Number you navigate to an external catalog with parts. The link can, for example, reference McMaster, DigiKey, or an Octopart library. This method won’t create significant overhead managing Part Numbers. The search mechanism in OpenBOM allows you to easily find Part Numbers in any BOM.

- Defining a Part Number for every Item in a BOM

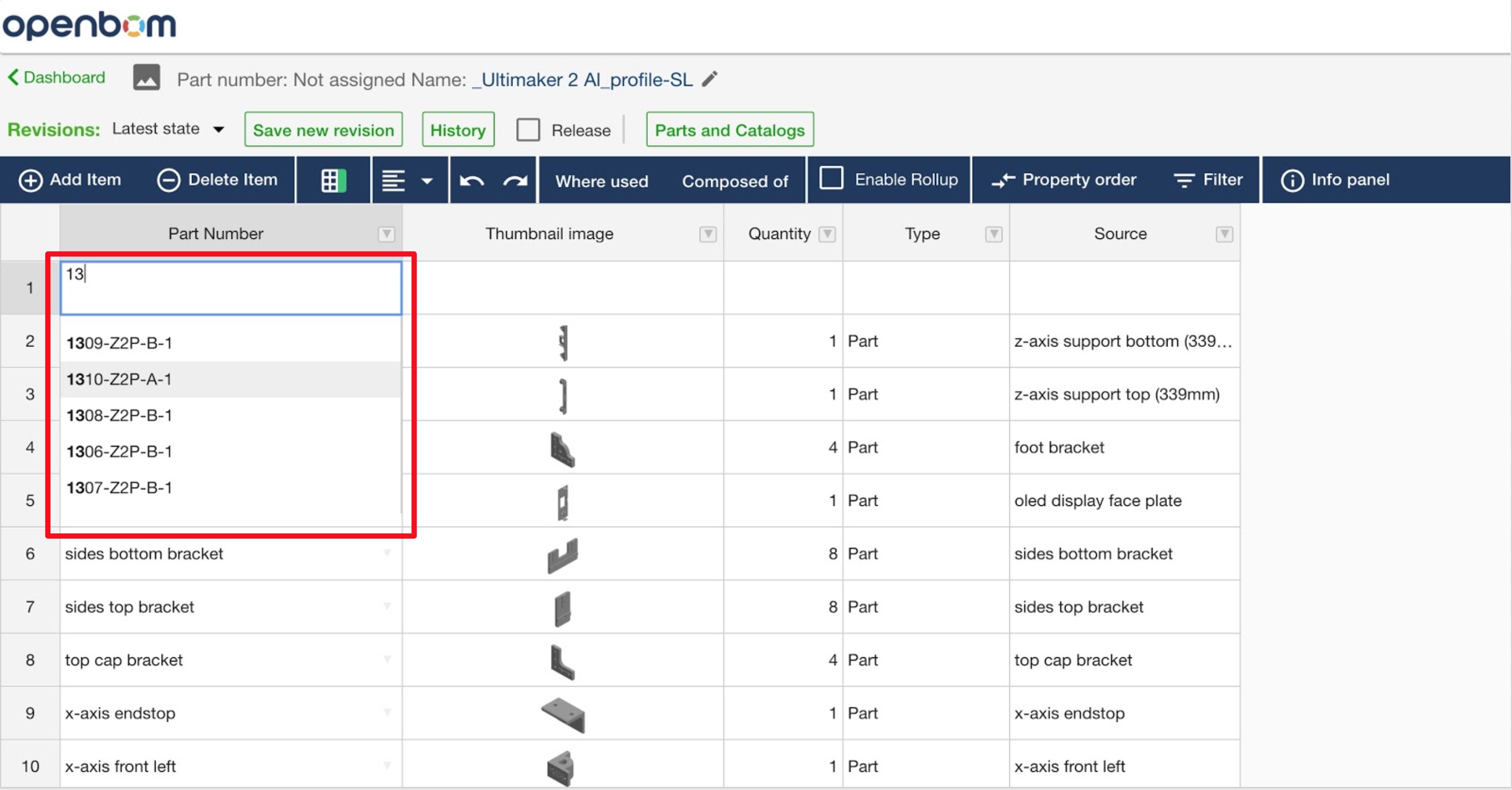

I’d recommend the definition of Part Numbers as a minimum requirement for creating reliable Bill of Materials. In many small teams, engineers prefer to use the same Number for both documents and parts. This is not an ideal situation but can work if your team is small and you don’t want to create loads of overhead managing Part Numbers.

The type-ahead ahead functionality allows you to select an available Part Number that was previously used (in any BOM) when you add a new Item to a BOM. This makes it easy for an engineer to leverage pre-existing Part Numbers.

- Part Catalog

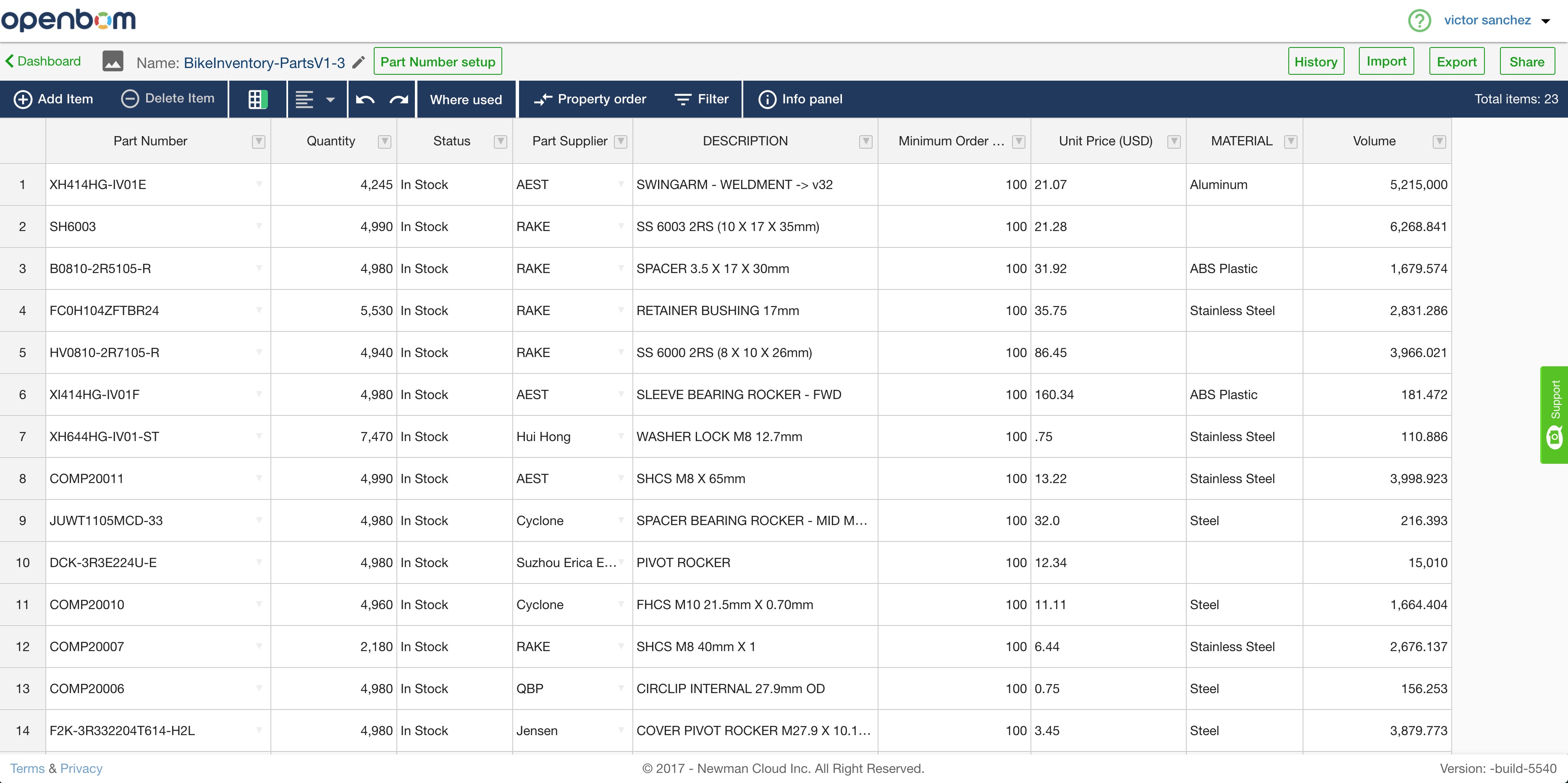

OpenBOM gives you the ability to create and manage Part Catalogs with Part Numbers in an OpenBOM catalog and uses these Part Number as a primarily way to define Parts. This is, in my opinion, the right way to go. You define a unique record for every Part Number and define additional properties for items in the catalog, e.g., Manufacturer, MPN, Description, Available stock, Supplier information, etc. These characteristics will be shared with all Bill of Materials you create in openBoM.

Creating Part Numbers thus creates a new Inventory (parts catalog) with additional useful properties. Here’s an example of a part catalog created in OpenBOM:

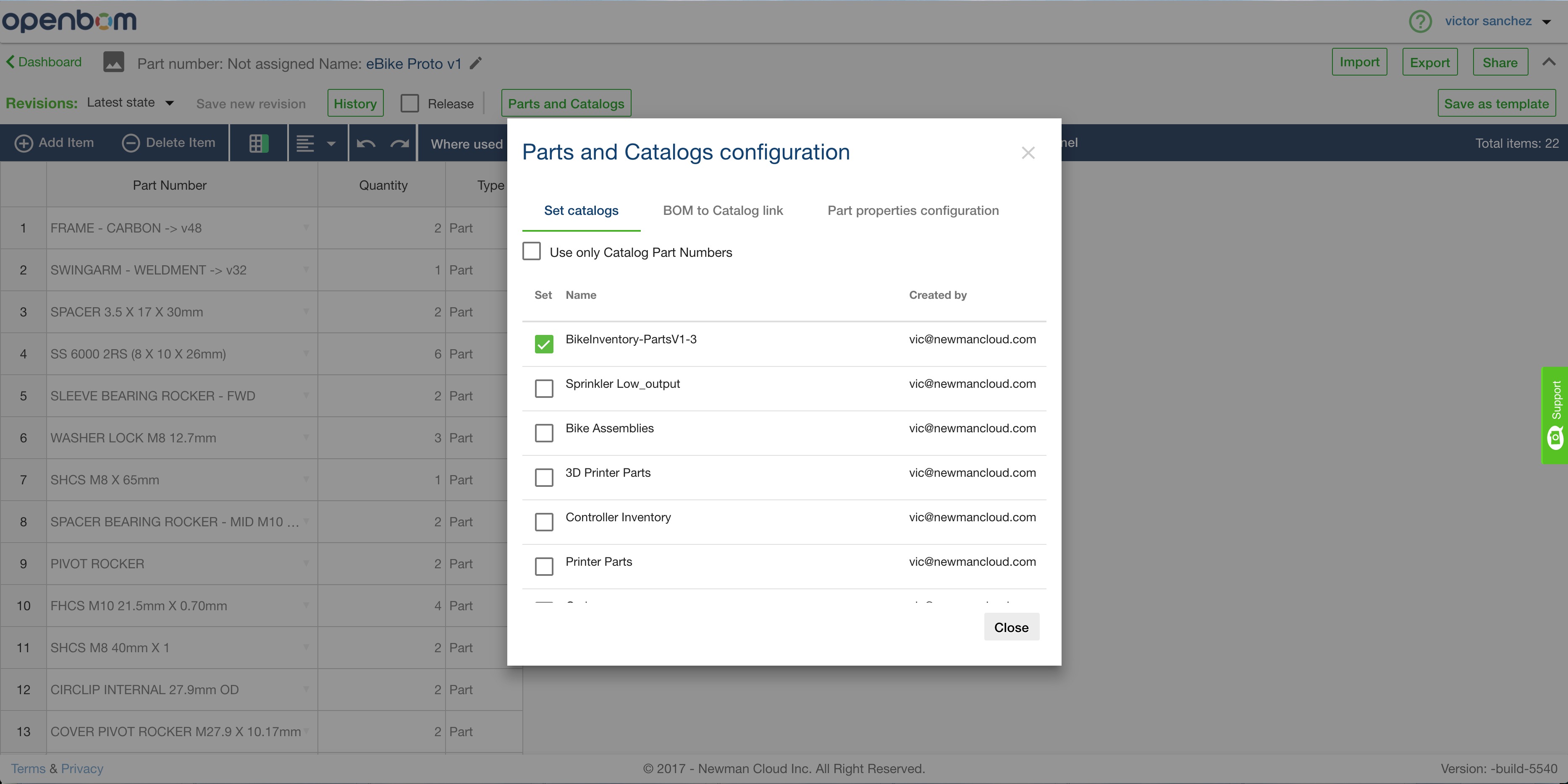

When you create a BOM, you can assign a part catalog to BOM. From that moment on, Part Number fields in a BOM will provide a searchable list of Parts from the assigned Inventories. In the example below, the Bike catalog, above, has been assigned to a BOM. Any Part Numbers from this catalog can be selected as required.

Part Number management can add considerable overhead to your project. On the other hand, Part Numbers can also help you organize and classify parts. Part Numbers improve the product data management of your product, hardware projects, and that of your engineering and manufacturing organization. OpenBOM provides a set of flexible tools to organize and manage Part Numbers without adding an undesirable level of complexity.