OpenBOM™ is a registered Trademark of Newman Cloud, Inc. | © 2022

- Home

- Training Courses

- OpenBOM Basics Course

- Registration & Settings

- Dashboard Walkthrough & Searches

- Creating BOMs from Excel

- Creating BOMs from CAD

- Creating BOMs Manually

- Preparing Catalogs

- Multi-Level & Flattened BOMs

- Exporting Reports

- Creating User-Defined Views & Filtering Information

- Real-Time Collaboration

- Revision & Change Management

- Managing Your Team

- OpenBOM Data Management Course

- OpenBOM Change Management Course

- End-to-End Design to Purchase Process

- Introduction

- 1. Install OpenBOM Add-In

- 2. Sign into OpenBOM

- 3. Edit Your Settings

- 4. Create a BOM Using the One-Click BOM

- 5. Create a Vendor List

- 6. Open Your CAD Items Catalog

- 7. Add Business Data to Your Items (Vendors and Costs)

- 8. Order Long-Lead Items

- 9. Mark a Purchase Order as “Received” in OpenBOM

- 10. Create an Order BOM

- 11. Create a Purchase Order

- 12. Export a Purchase Order

- OpenBOM CAD Integration Courses

- OpenBOM Design Course

- Premium Onboarding Experience

- OpenBOM Basics Course

- Getting Started

- Video Demos

- OpenBOM Basics

- Training Courses

- Part Number Management

- Import Data

- Design Projects

- New Product Development Process

- CAD Integrations

- Bill of Materials

- OpenBOM Community

- “Where Used” and Graph Navigation

- Flattened BOM Feature

- Generate PDFs (and More) from CAD

- Generate Part Numbers for CAD

- Create RFQs and POs

- Manage Revisions of Attached Files

- Export Data as a Zip

- OpenBOM YouTube Channel

- Administration

- Data Management

- Properties

- File Management

- Search & Filters

- BOM Types

- Creating BOMs

- BOM Compare Service

- Formulas, Calculations, & Rollups

- Organizing Data

- Custom Objects

- Design Projects

- Using Templates

- Exporting Data

- User-Defined Views

- Team Views

- Collaborate & Share

- Production Planning & Inventory Control

- Change Management and Revision Control

- User Defined Commands

- xBOM Types

- Integrations

- Home

- Training Courses

- OpenBOM Basics Course

- Registration & Settings

- Dashboard Walkthrough & Searches

- Creating BOMs from Excel

- Creating BOMs from CAD

- Creating BOMs Manually

- Preparing Catalogs

- Multi-Level & Flattened BOMs

- Exporting Reports

- Creating User-Defined Views & Filtering Information

- Real-Time Collaboration

- Revision & Change Management

- Managing Your Team

- OpenBOM Data Management Course

- OpenBOM Change Management Course

- End-to-End Design to Purchase Process

- Introduction

- 1. Install OpenBOM Add-In

- 2. Sign into OpenBOM

- 3. Edit Your Settings

- 4. Create a BOM Using the One-Click BOM

- 5. Create a Vendor List

- 6. Open Your CAD Items Catalog

- 7. Add Business Data to Your Items (Vendors and Costs)

- 8. Order Long-Lead Items

- 9. Mark a Purchase Order as "Received" in OpenBOM

- 10. Create an Order BOM

- 11. Create a Purchase Order

- 12. Export a Purchase Order

- OpenBOM CAD Integration Courses

- OpenBOM Design Course

- Premium Onboarding Experience

- OpenBOM Basics Course

- Getting Started

- Video Demos

- OpenBOM Basics

- Training Courses

- Part Number Management

- Import Data

- Design Projects

- New Product Development Process

- CAD Integrations

- Bill of Materials

- OpenBOM Community

- "Where Used" and Graph Navigation

- Flattened BOM Feature

- Generate PDFs (and More) from CAD

- Generate Part Numbers for CAD

- Create RFQs and POs

- Manage Revisions of Attached Files

- Export Data as a Zip

- OpenBOM YouTube Channel

- Administration

- Data Management

- Properties

- File Management

- Search & Filters

- BOM Types

- Creating BOMs

- BOM Compare Service

- Formulas, Calculations, & Rollups

- Organizing Data

- Custom Objects

- Design Projects

- Using Templates

- Exporting Data

- User-Defined Views

- Team Views

- Collaborate & Share

- Production Planning & Inventory Control

- Change Management and Revision Control

- User Defined Commands

- xBOM Types

- Integrations

xBOM Types (EBOM, MBOM, SBOM, etc)

This page and set of resources will help you learn how to create different type of BOMs – EBOM, MBOM, SBOM, etc. )

- Introduction

- Understanding xBOM and Product Structures

- 2.1 Key Product Lifecycle Stages

- 2.2 Importance of Multiple BOM Types

- Features of the OpenBOM xBOM Service

- 3.1 Multi-View BOM Architecture

- 3.2 Graph-Based Data Model

- 3.3 User Experience and Interface

- 3.4 Role-Based Access Control

- Setting Up xBOM Types

- 4.1 Admin Configuration

- 4.2 Defining BOM Templates

- Managing Multiple BOM Types

- 5.1 Creating and Editing BOMs

- 5.2 Switching Between BOM Types

- 5.3 Where-Used Query and Navigation

- Practical Examples of BOM Types

- 6.1 Simple BOM

- 6.2 Engineering BOM (EBOM)

- 6.3 Manufacturing BOM (MBOM)

- 6.4 Support and Service BOM (SBOM)

- 6.5 Functional BOM

- Advanced Features and Future Enhancements

- 7.1 Revision Management and Change Control

- 7.2 Graph Navigation and Advanced BOM Comparison

- Using xBOM for Complex Subsystem Modeling and Cost Estimation

- 8.1 Subsystem Data Modeling

- 8.2 Cost Calculation and Rollups

- Unlocking the Digital Thread with xBOM

- 9.1 Digital Thread Architecture

- 9.2 Enabling a Distributed Digital Thread

- Articles and Live Demo Links

- Conclusion

Introduction

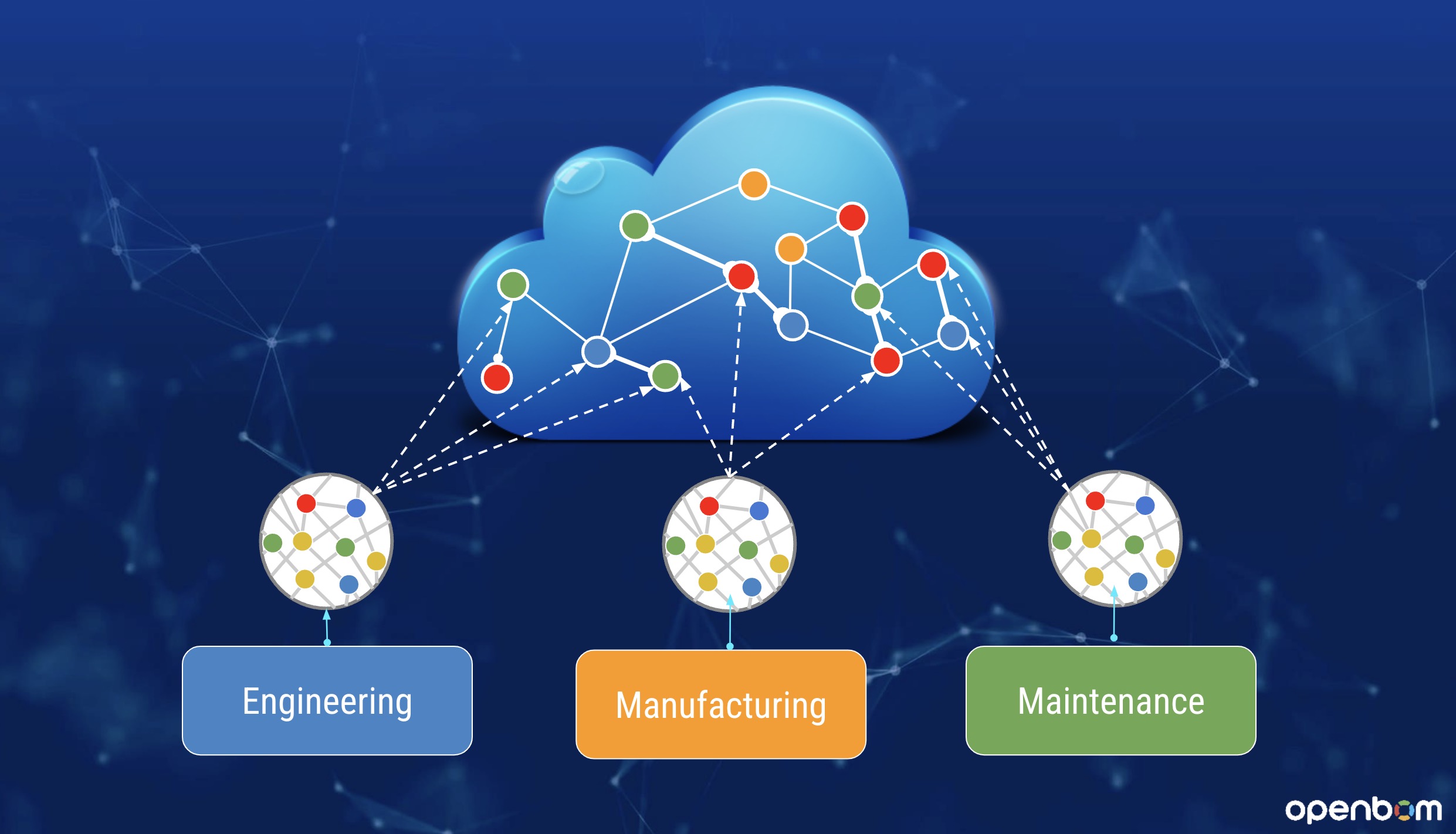

OpenBOM’s xBOM service is a transformative tool that empowers companies to efficiently manage multiple product structures across different lifecycle stages. The challenge for many organizations is to a multiple databases or data sources with information related to engineering, manufacturing, maintenance, and others. How to connect this information and manage it in a cohesive way? This is a problem many organizations are looking to solve.

By introducing the concept of xBOM (BOM types), OpenBOM provides a robust framework for modeling complex products from engineering through manufacturing and into service and maintenance. The xBOM service allows users to create, manage, and navigate through various BOM types, ensuring that each department within an organization has access to the relevant product data they need.

This documentation provides an in-depth guide to the OpenBOM xBOM service, detailing its features, setup process, and use cases, as well as advanced functionalities like revision management, cost estimation, and the integration of a digital thread across multiple systems.

Understanding xBOM and Product Structures

In engineering and manufacturing, data is inherently structured and interconnected. Product structures are the backbone of this interconnected data, spanning from basic assembly-component relationships to complex systems that include assemblies, ordering, and maintenance parts.

2.1 Key Product Lifecycle Stages

Product structures play a crucial role in creating lifecycle models of data, ensuring that every stage of the product lifecycle is properly managed. The key stages include:

- Engineering: Focuses on the design and specification of the product, including detailed part lists and assembly instructions.

- Production Planning: Involves organizing the production process, ensuring that resources and schedules are aligned.

- Manufacturing: The execution stage where the product is assembled, tested, and prepared for delivery.

- Maintenance: Post-production support, including service, repairs, and replacement parts management.

- Others: Additional stages may include sales, customer support, and disposal or recycling.

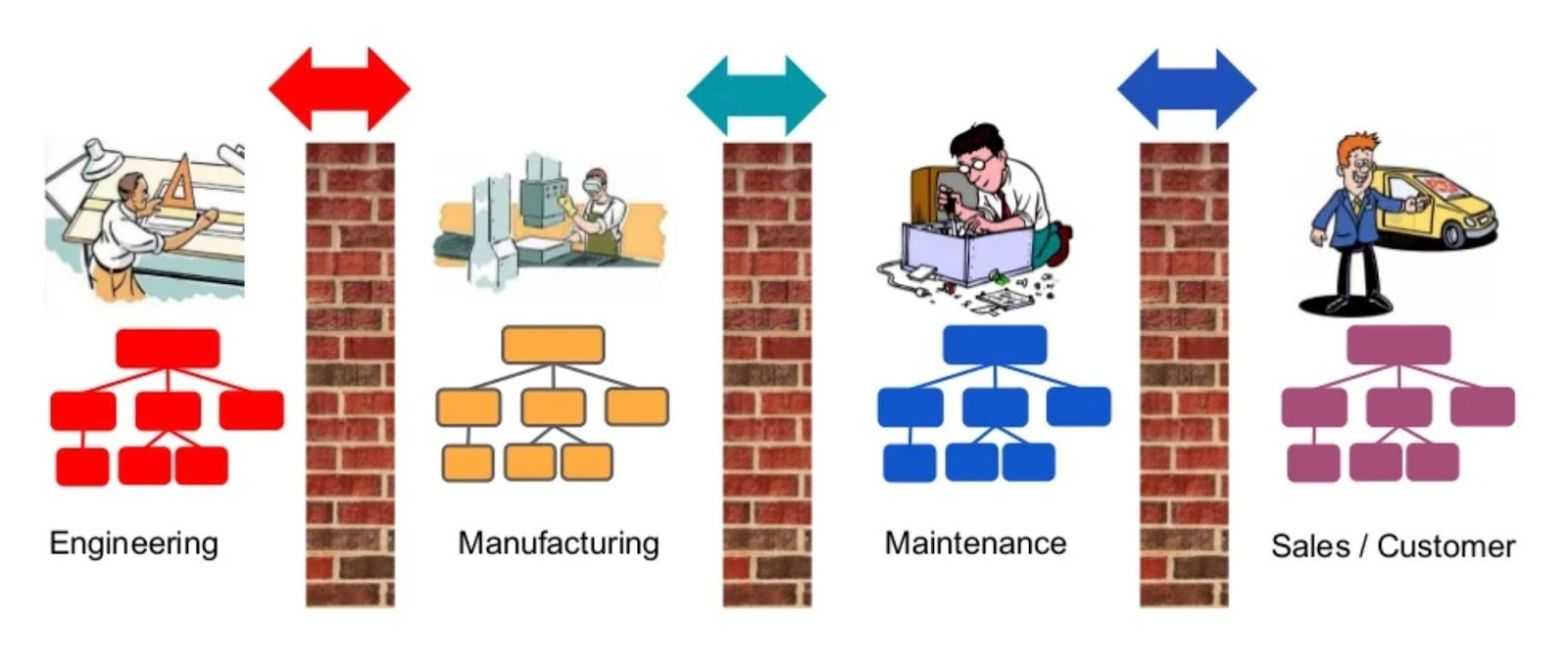

2.2 Importance of Multiple BOM Types

Different stakeholders within an organization require different representations of the product to perform their tasks effectively. For instance:

- Engineering teams need a BOM that represents the design structure, including all assemblies, components, and specifications.

- Manufacturing teams require a BOM that outlines the assembly process, including the sequencing of operations.

- Maintenance teams rely on a BOM that highlights replacement parts and maintenance procedures.

OpenBOM’s xBOM service introduces the ability to create and manage multiple BOM types for the same product, allowing for tailored views that meet the specific needs of each department.

Features of the OpenBOM xBOM Service

OpenBOM’s xBOM service offers a range of features designed to simplify and enhance the management of product structures across different lifecycle stages.

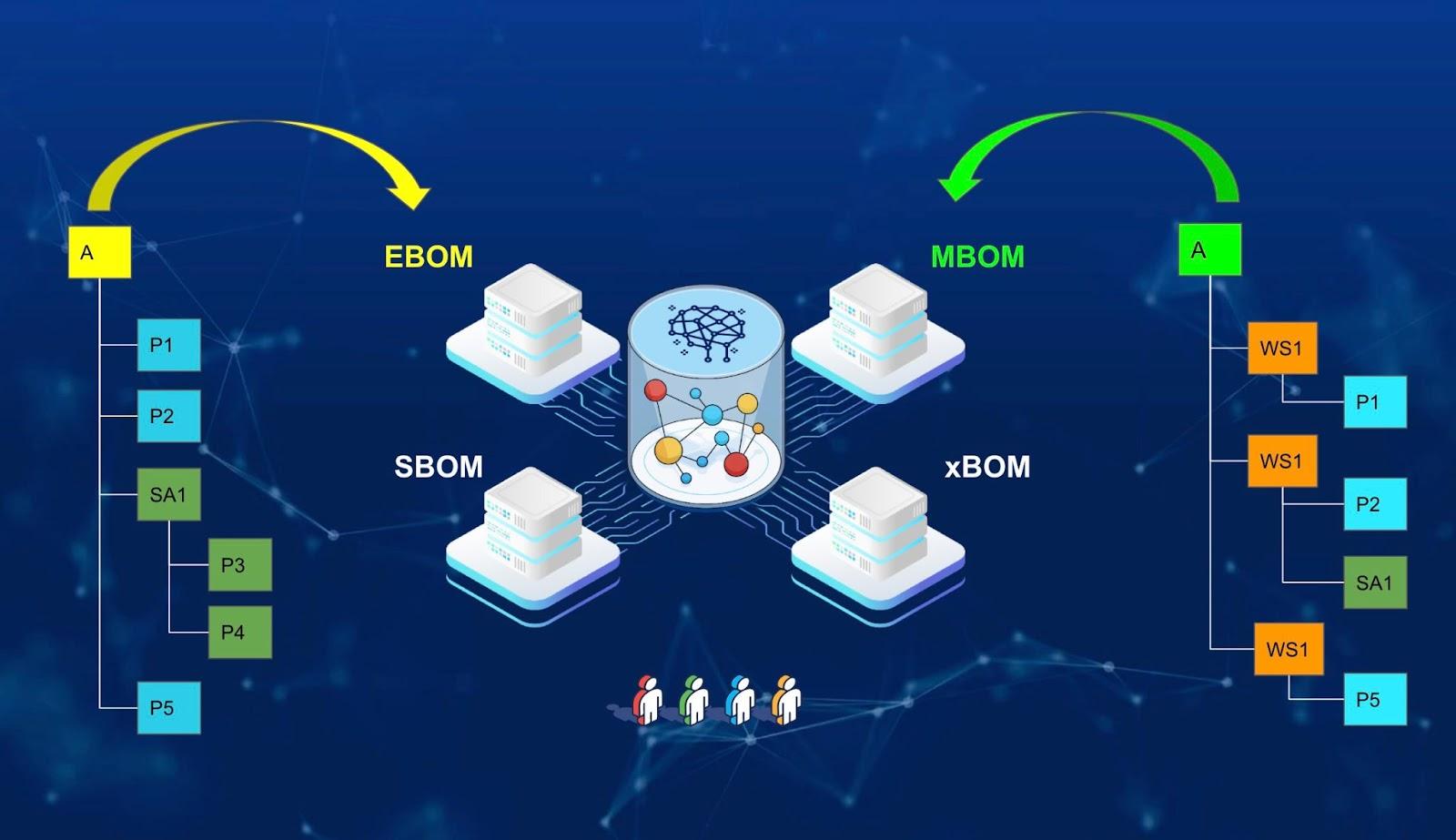

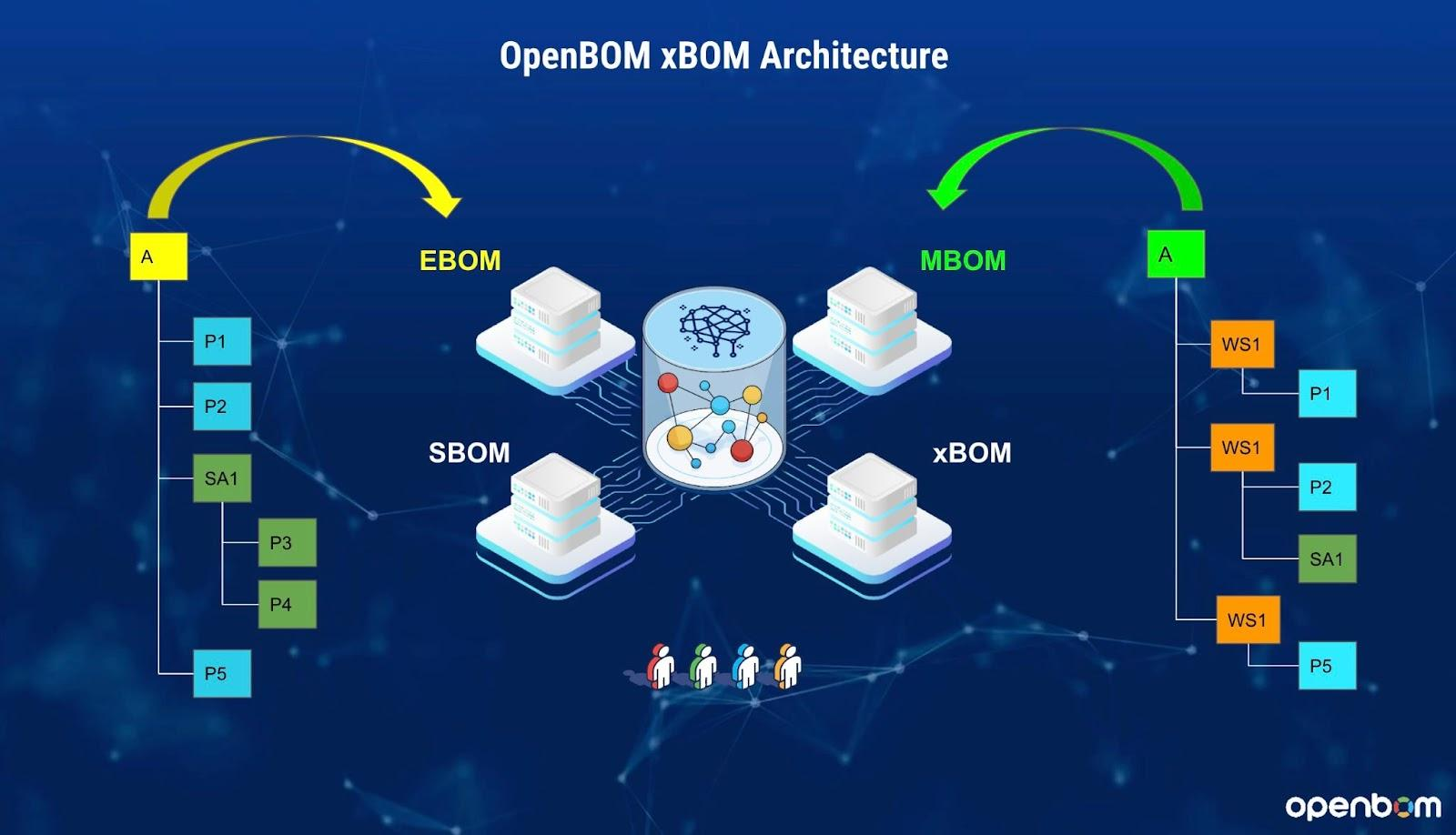

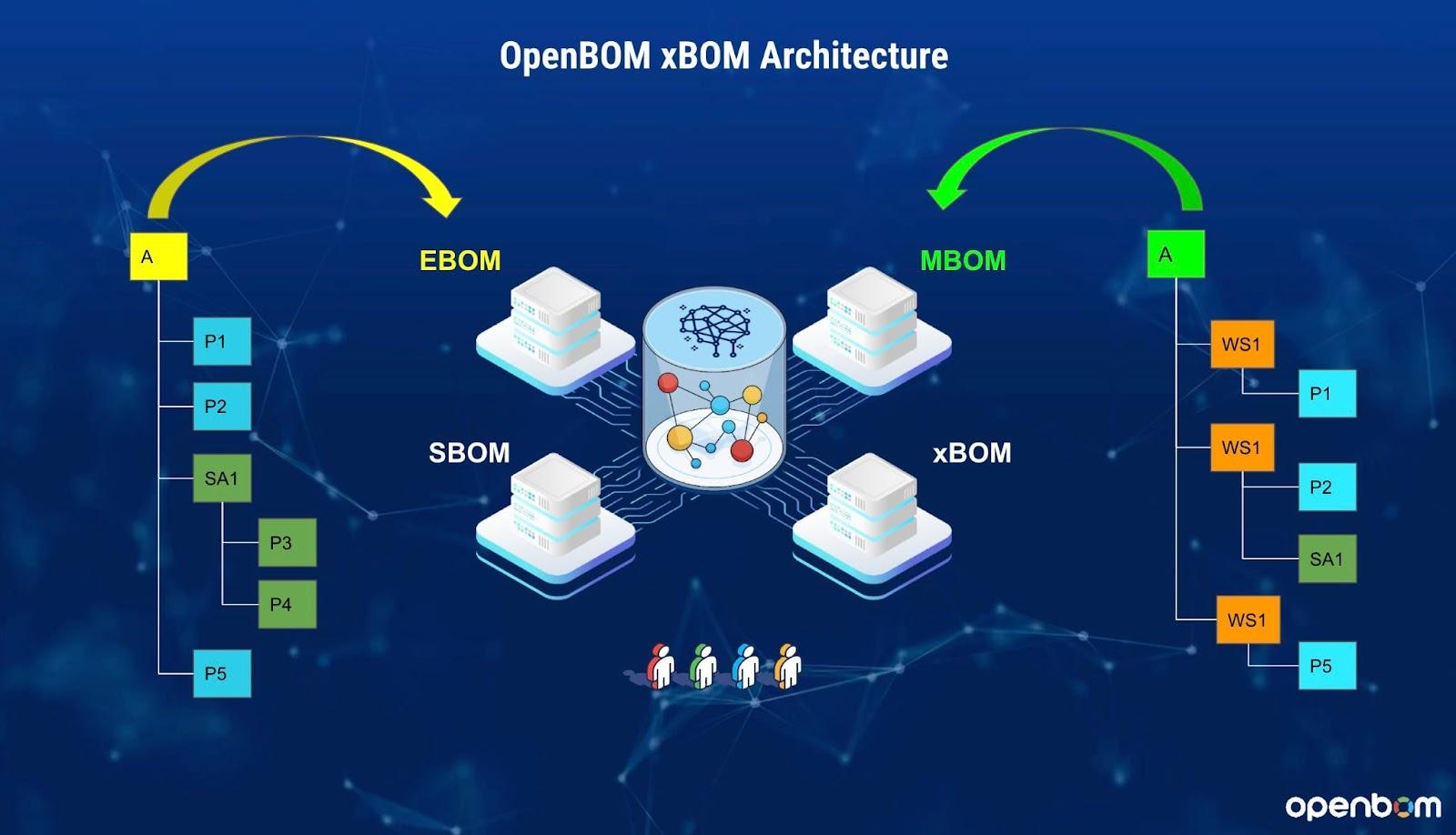

3.1 Multi-View BOM Architecture

At the core of the xBOM service is a multi-view BOM architecture. This architecture allows users to define multiple “structures” or BOM types, all connected to the same top assembly part number.

These structures provide a virtual management framework for different product representations, such as:

- Engineering BOM (EBOM)

- Manufacturing BOM (MBOM)

- Support and Service BOM (SBOM)

- Functional BOM (FBOM)

This multi-view approach ensures that all relevant information is accessible and up-to-date across different stages of the product lifecycle.

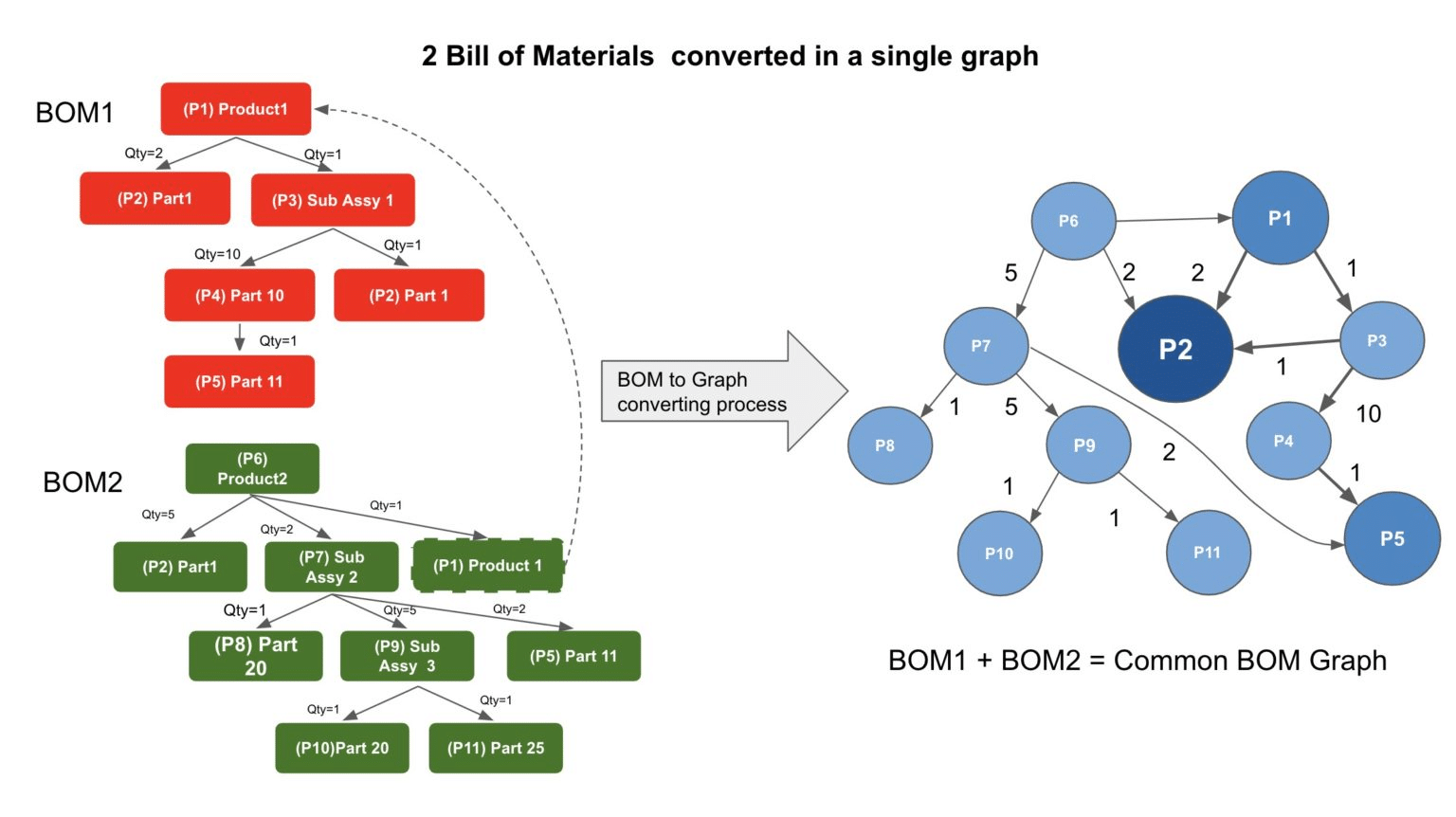

3.2 Graph-Based Data Model

The xBOM service leverages a graph-based data model, which is fundamental to its flexibility and scalability. The graph model organizes data, connections, and relationships within the product structure, allowing for independent multi-view representations of the BOM. This architecture supports complex product configurations and ensures that data integrity is maintained across different BOM types.

3.3 User Experience and Interface

The xBOM service is designed with a user-friendly interface that integrates seamlessly into the existing OpenBOM platform. Key features include:

- BOM Type Selection: Users can easily select the type of BOM they wish to create or edit from a drop-down menu.

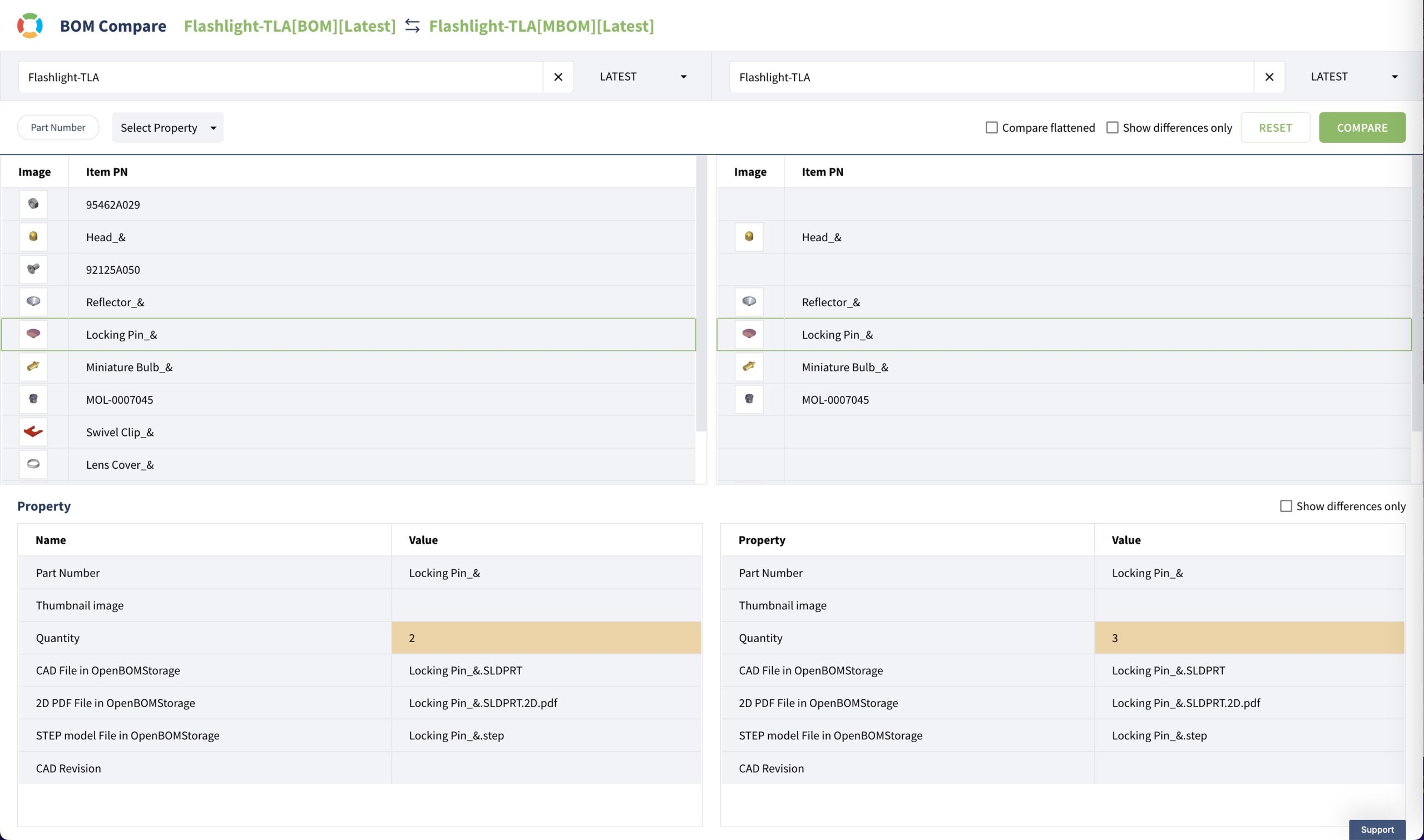

- BOM Comparison: A powerful feature that allows users to compare different BOM types side-by-side, facilitating better decision-making.

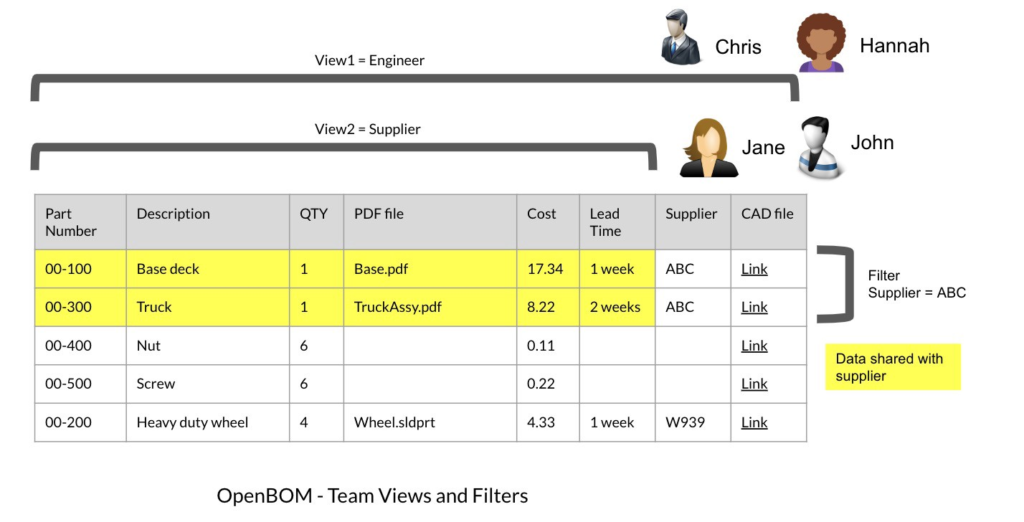

- Role-Based Views: Access to specific BOM types is controlled based on user roles, ensuring that each department only interacts with the data relevant to their tasks.

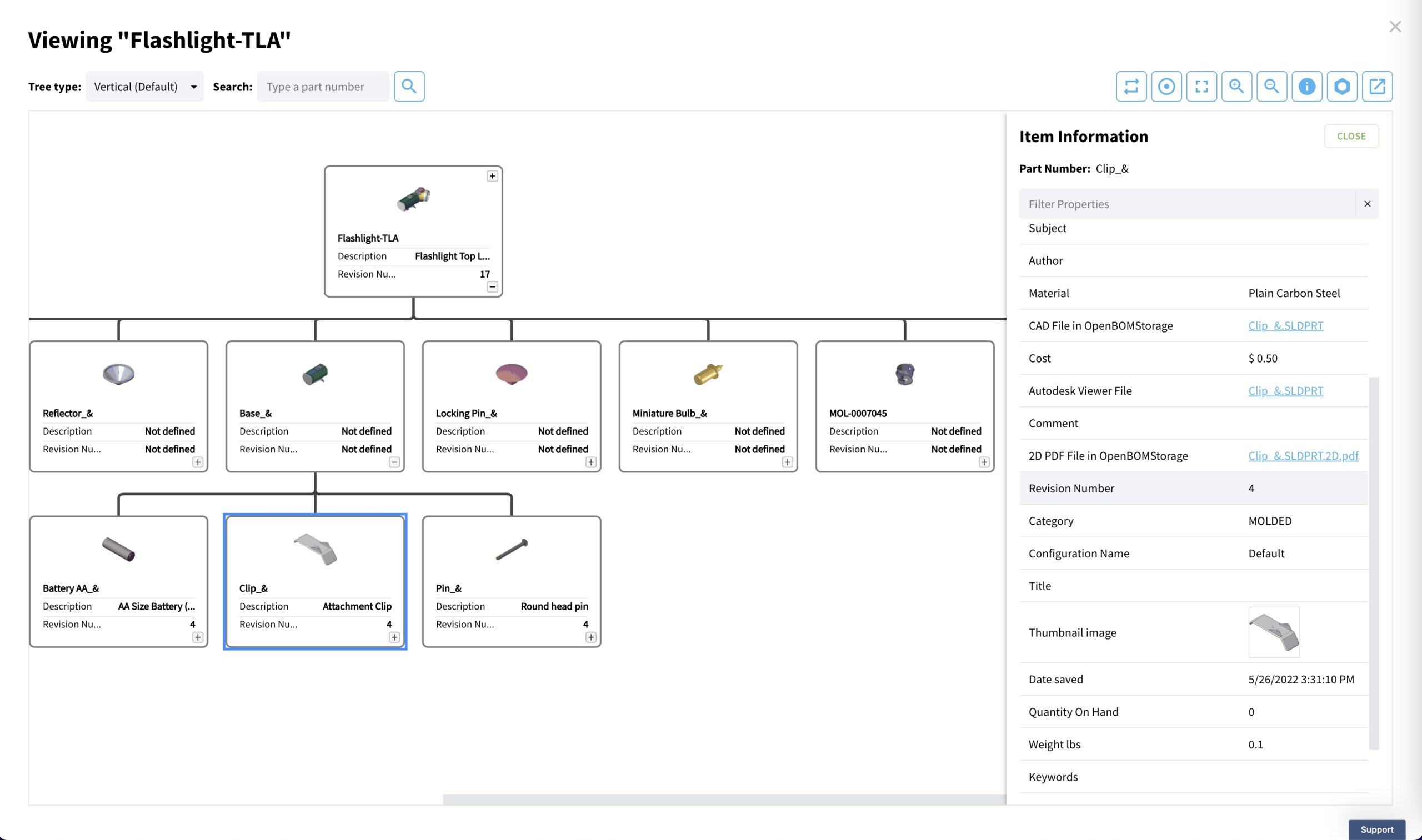

You can use graph navigation

and BOM compare capabilities to explore multi-view BOM structure.

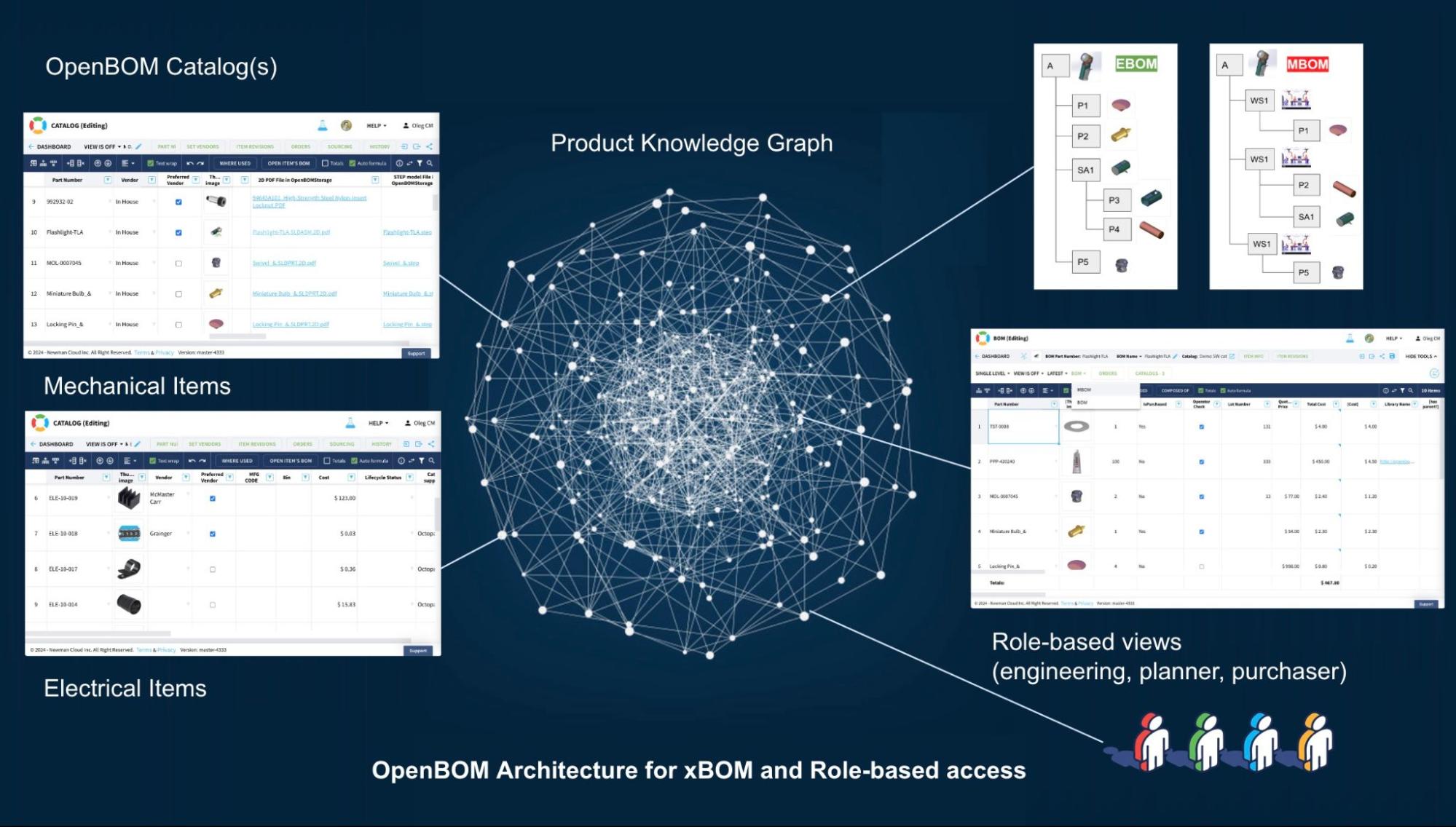

3.4 Role-Based Access Control

Role-based access control is a critical feature of the xBOM service, providing different user groups (e.g., engineers, procurement specialists, production engineers) with access to specific views and data. This ensures that sensitive information is protected while promoting efficient collaboration across the organization.

3.5 Five Elements of OpenBOM xBOM Architecture

The OpenBOM xBOM architecture is built on five key elements, each playing a crucial role in supporting flexible data management and access control:

- Object Model for Flexible Data Management The foundation of our architecture is the object model, which facilitates the definition and management of item catalogs. This model allows users to create a structured and adaptable framework for their data, ensuring that all product information is accurately captured and easily accessible. Check more information about the OpenBOM data model and how OpenBOM delivers the flexibility of the data model for our customers.

- Product Knowledge Graph Our Product Knowledge Graph is a sophisticated tool used to define multiple relationships between data elements, such as BOMs and other related information. This graph-based approach enables a comprehensive view of product data, highlighting connections and dependencies that are essential for effective lifecycle management.

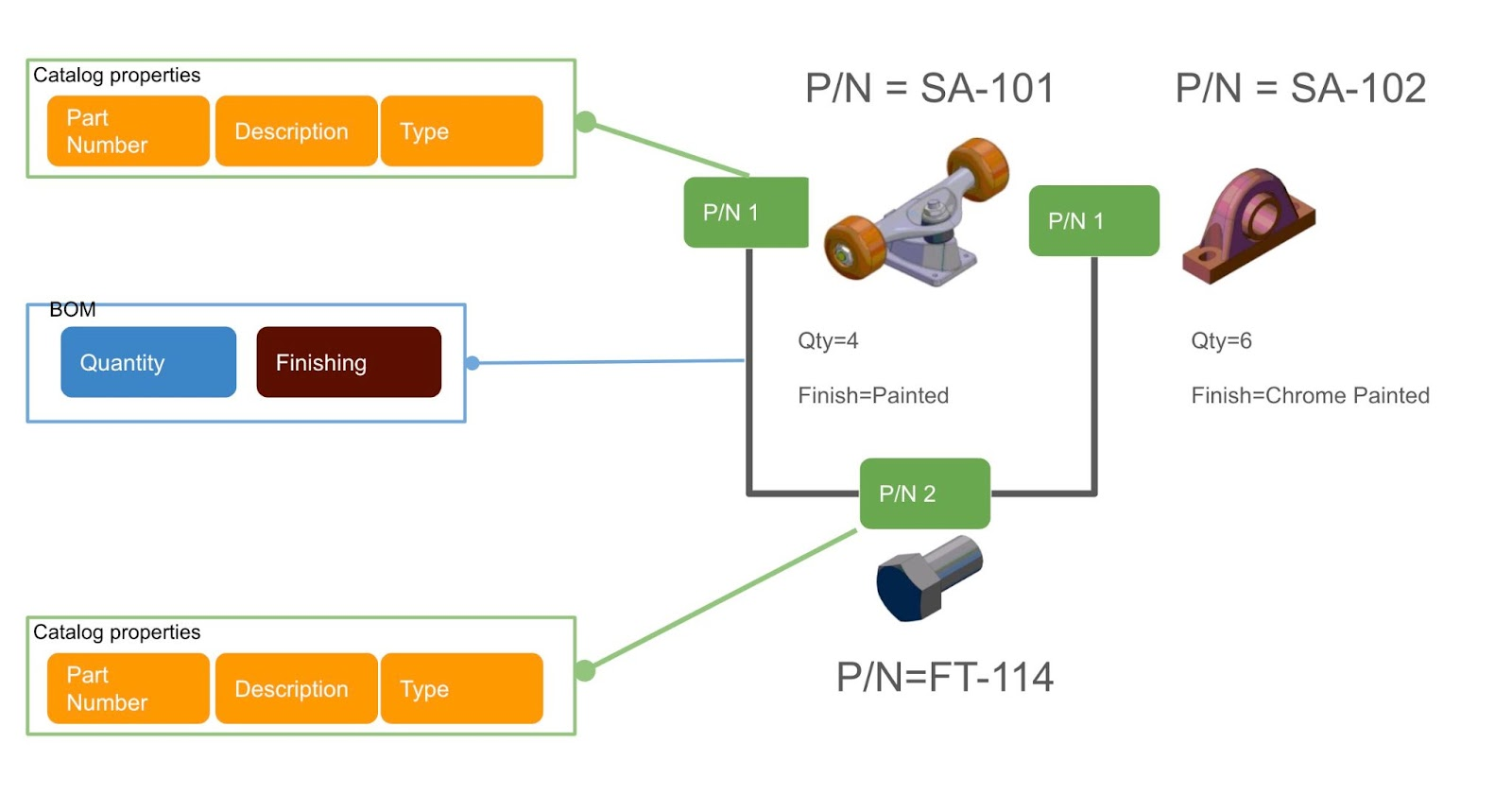

- BOM Data Modeling for Instance-Reference Relationships BOM data modeling is essential for managing the relationships between different instances and references within a product’s lifecycle. Essentially, these relationships allow you to build a product structure. This element ensures that all variations and configurations of a product are accurately represented, facilitating precise tracking and management.

- Specific BOM Types – EBOM and MBOM OpenBOM supports specific BOM types, such as Engineering BOM (EBOM) and Manufacturing BOM (MBOM), while maintaining complete flexibility for customization. Users can tailor these BOM types to meet their specific needs, ensuring that the architecture adapts to various use cases and requirements. This is a key element of the OpenBOM xBOM model.

- Role-Based Views for Access Control Role-based views are crucial for providing seamless data access to specific groups of users, such as engineers, procurement specialists, and production engineers. These views ensure that each user group has access to the information they need, enhancing collaboration and efficiency across the organization

Object Model for Flexible Data Management

The object model in OpenBOM is designed to handle diverse data types and structures. It allows users to define item catalogs with various attributes and relationships, supporting a dynamic and scalable data management approach.

Product Knowledge Graph

The Product Knowledge Graph leverages graph database principles to map out complex relationships between different data elements. This method provides a clear and interconnected view of all product-related information, facilitating better decision-making and lifecycle management.’

BOM Data Modeling for Instance-Reference Relationships

By modeling instance-reference relationships, OpenBOM ensures that each variation of a product is accurately documented. This approach supports configuration management and helps track changes and updates throughout the product life cycle.

Specific BOM Types – EBOM and MBOM

OpenBOM’s flexibility in defining different BOM types (eg. EBOM and MBOM) allows users to customize these BOMs to fit their specific workflows. This customization capability ensures that the BOMs align with the unique processes and requirements of each organization.

Role-Based Views for Access Control Role-based views in OpenBOM provide targeted access to data, ensuring that users see only the information relevant to their roles. This approach enhances security, improves workflow efficiency, and supports effective collaboration across different departments.

Three Unique Differentiators of OpenBOM Architecture

- Multi-Tenant Framework OpenBOM’s architecture is built on a multi-tenant framework, enabling multiple users and organizations to share the same infrastructure while maintaining data isolation and security. This design supports scalability and cost-effectiveness, making it an ideal solution for companies of all sizes.

- Graph-Based Data Management The use of a graph-based approach for data management allows OpenBOM to handle complex relationships and dependencies with ease. This method provides a more intuitive and interconnected view of product data, facilitating better analysis and decision-making.

- Real-Time Collaboration and Instant Data Sharing OpenBOM’s architecture supports real-time collaboration and instant data sharing, enabling teams to work together seamlessly, regardless of their physical location. This capability enhances productivity and ensures that all stakeholders have access to the most up-to-date information.

Setting Up xBOM Types

To fully utilize the xBOM service, proper setup is essential. The following steps outline the process for configuring and managing xBOM types within an organization.

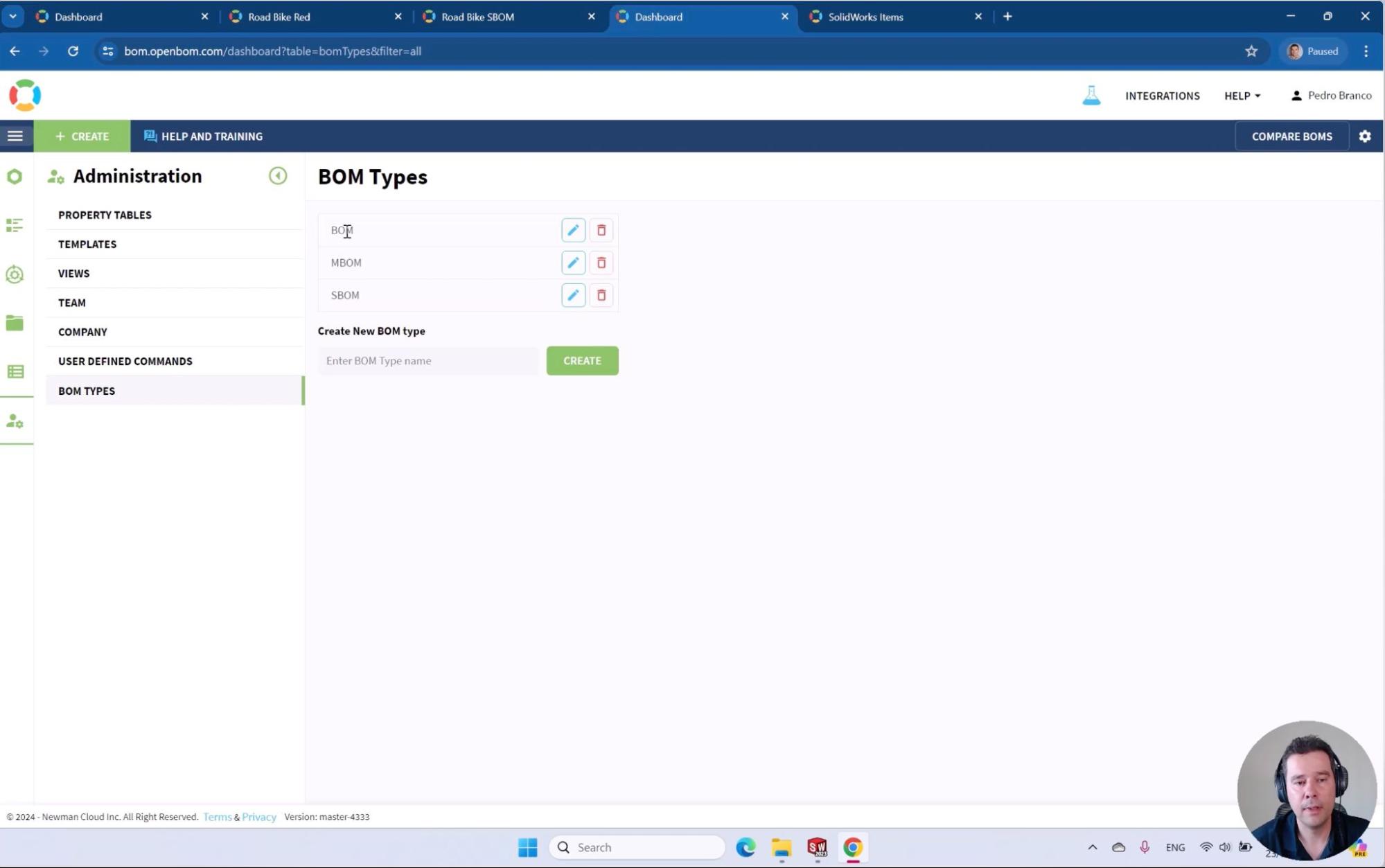

4.1 Admin Configuration

The initial setup of xBOM types is performed by the company administrator. This process includes:

- Accessing the Admin Panel: Log in to your OpenBOM account and navigate to the Admin dashboard.

- Creating New BOM Types: In the Admin Panel, select the option to create new BOM types. Assign names and descriptions that reflect their specific use cases, such as “EBOM” for engineering or “MBOM” for manufacturing.

- Defining Access Rights: Set permissions for each BOM type, determining which user roles can access, edit, or view specific BOMs.

4.2 Defining BOM Templates

To streamline the creation of BOMs, administrators can define templates for each BOM type. This process involves:

- Creating a Template: Start by creating a BOM that includes all necessary attributes based on the used catalogs and additional instance attributes.

- Saving the Template: Once the BOM is configured, save it as a template. Multiple templates can be created to cover various scenarios, ensuring consistency across the organization.

- Modifying Templates: If changes are needed, templates can be easily modified by updating the attributes and catalogs, then saving the template under the same name.

Managing Multiple BOM Types

Once the xBOM types are set up, users can begin creating, editing, and managing these BOMs according to their specific needs.

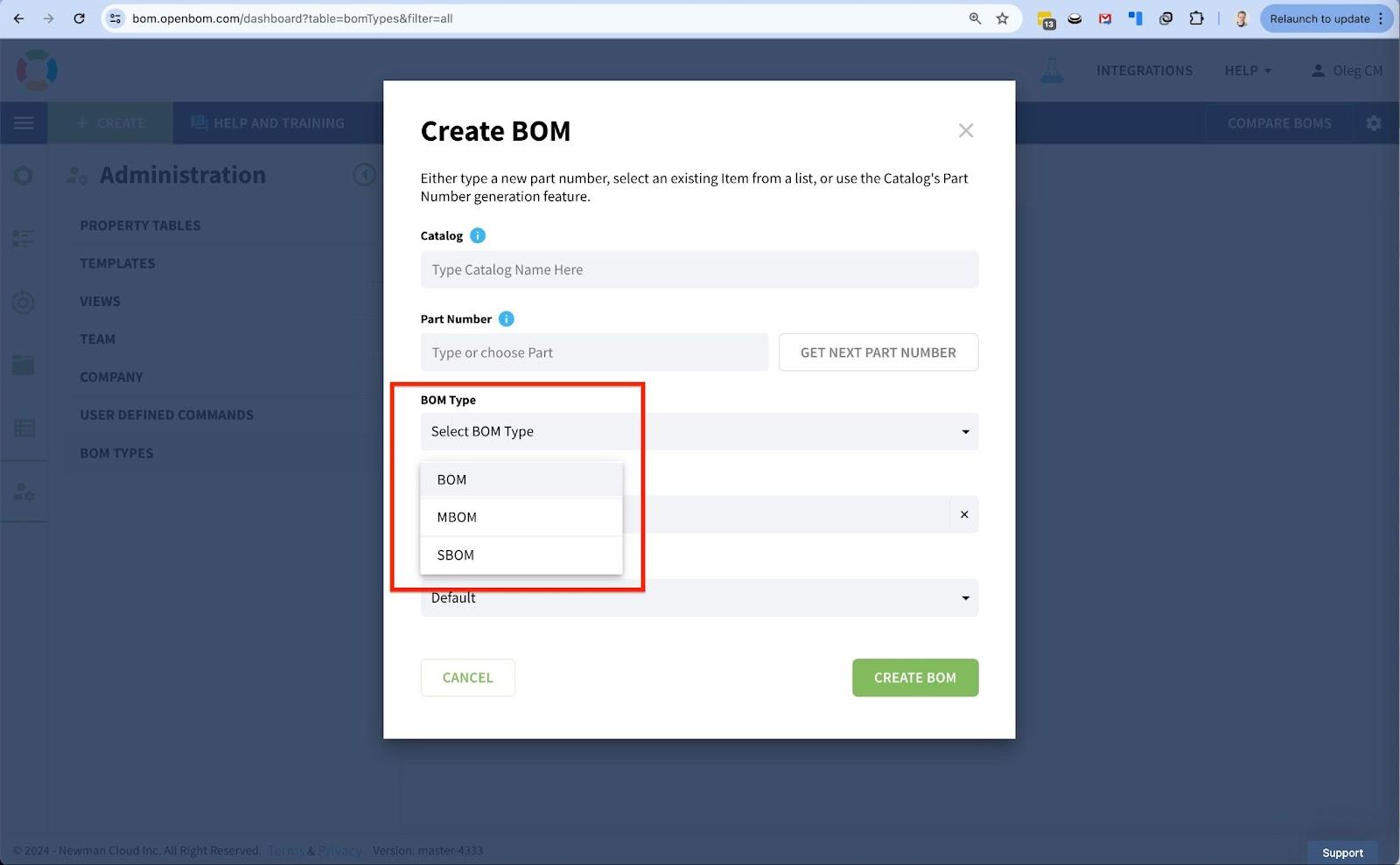

5.1 Creating and Editing BOMs

The creation and editing of BOMs are straightforward:

- Creating a New BOM: When creating a BOM, users must select the BOM type (e.g., EBOM, MBOM). If additional BOM types have not been defined, the process remains the same as in the standard OpenBOM interface.

- Editing BOMs: Each BOM type defined for a specific part number can be edited independently. Users must follow the BOM Type selection control to determine which BOM type they are editing.

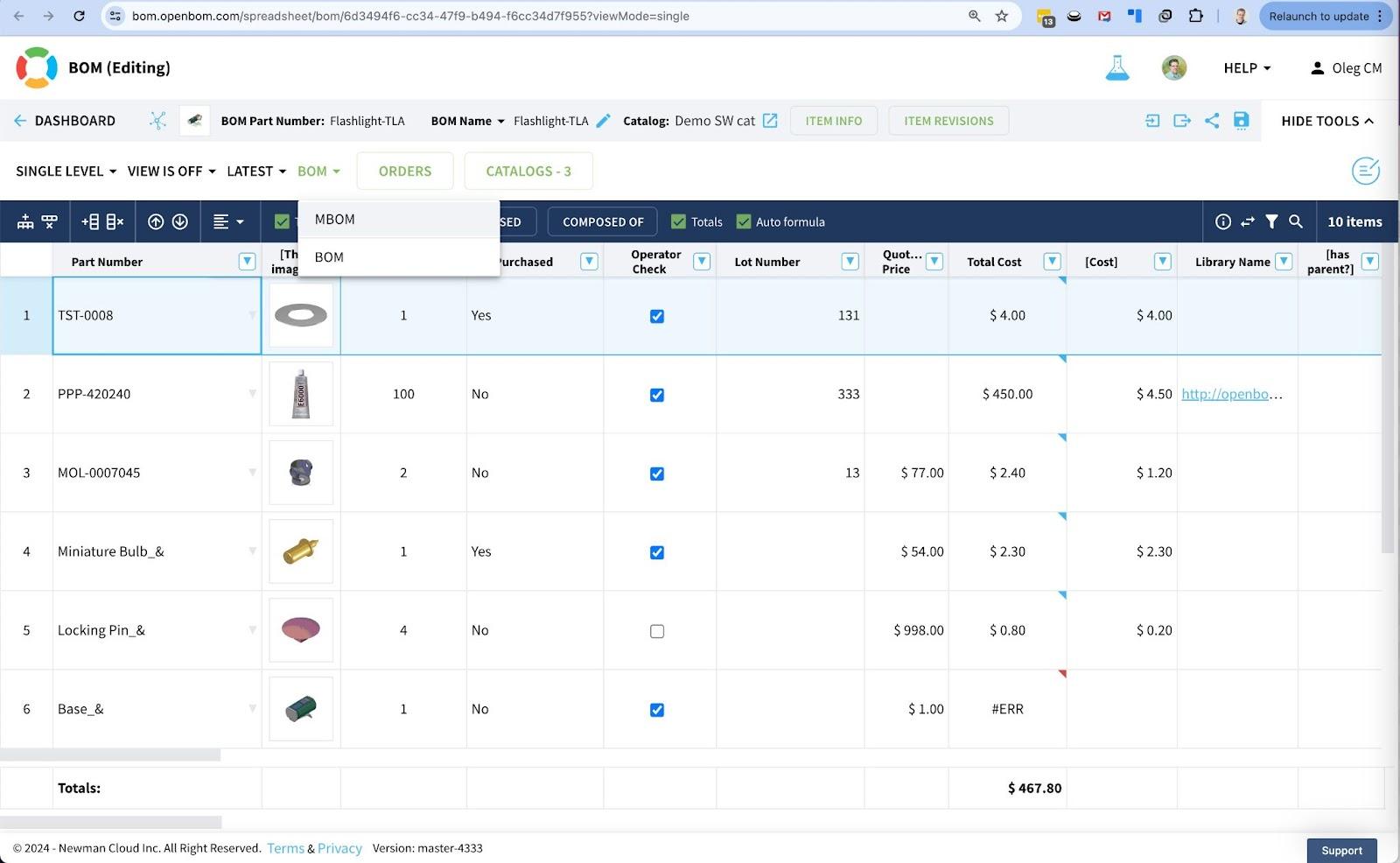

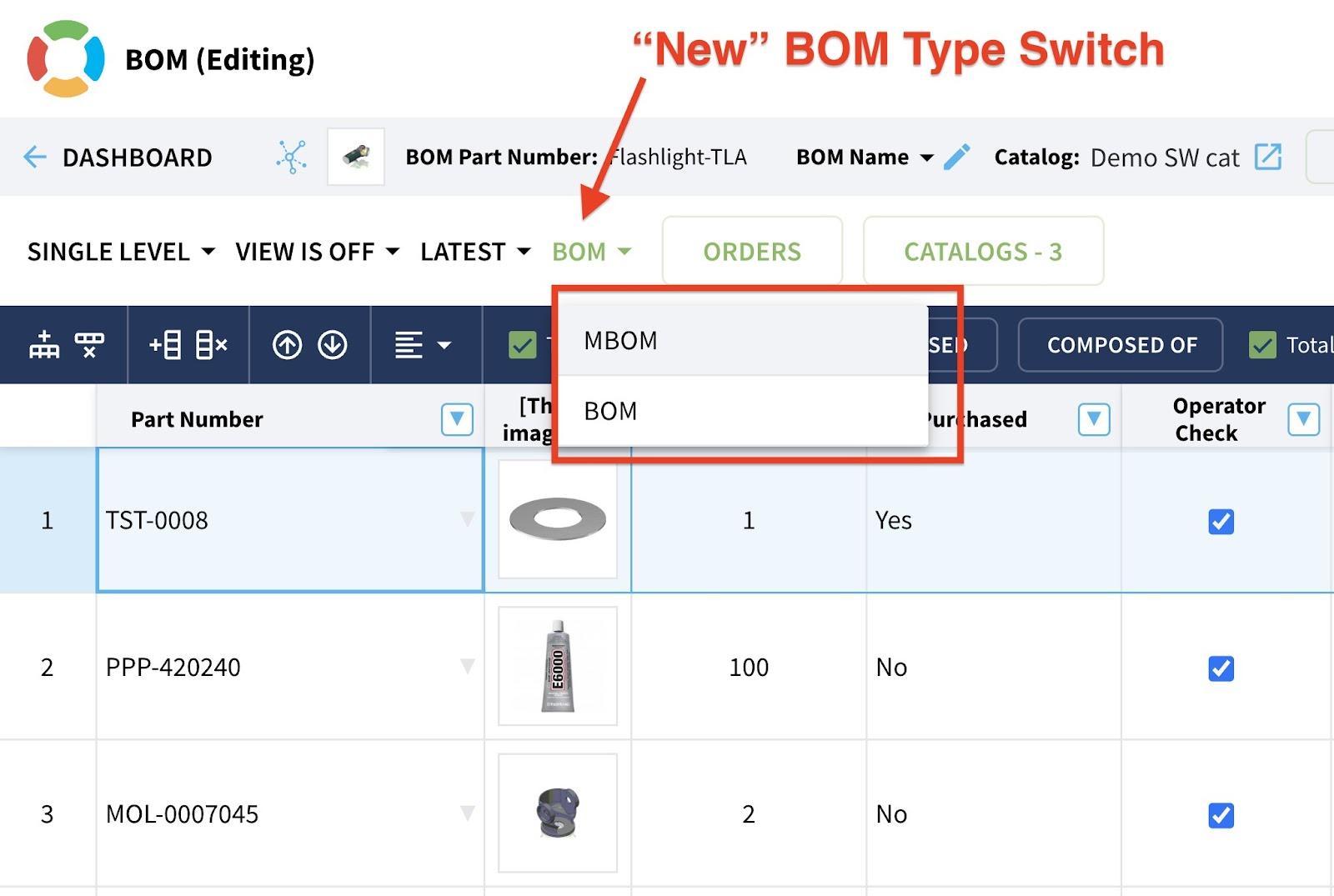

5.2 Switching Between BOM Types

Switching between different BOM types is simple and intuitive:

- Drop-Down Menu Navigation: Use the drop-down menu or navigation panel to select the desired BOM type. This feature allows users to quickly view and manage different BOMs without losing context.

- Opening Specific BOM Types: If multiple BOM types are connected to the same item, the interface allows users to open each specific BOM type individually.

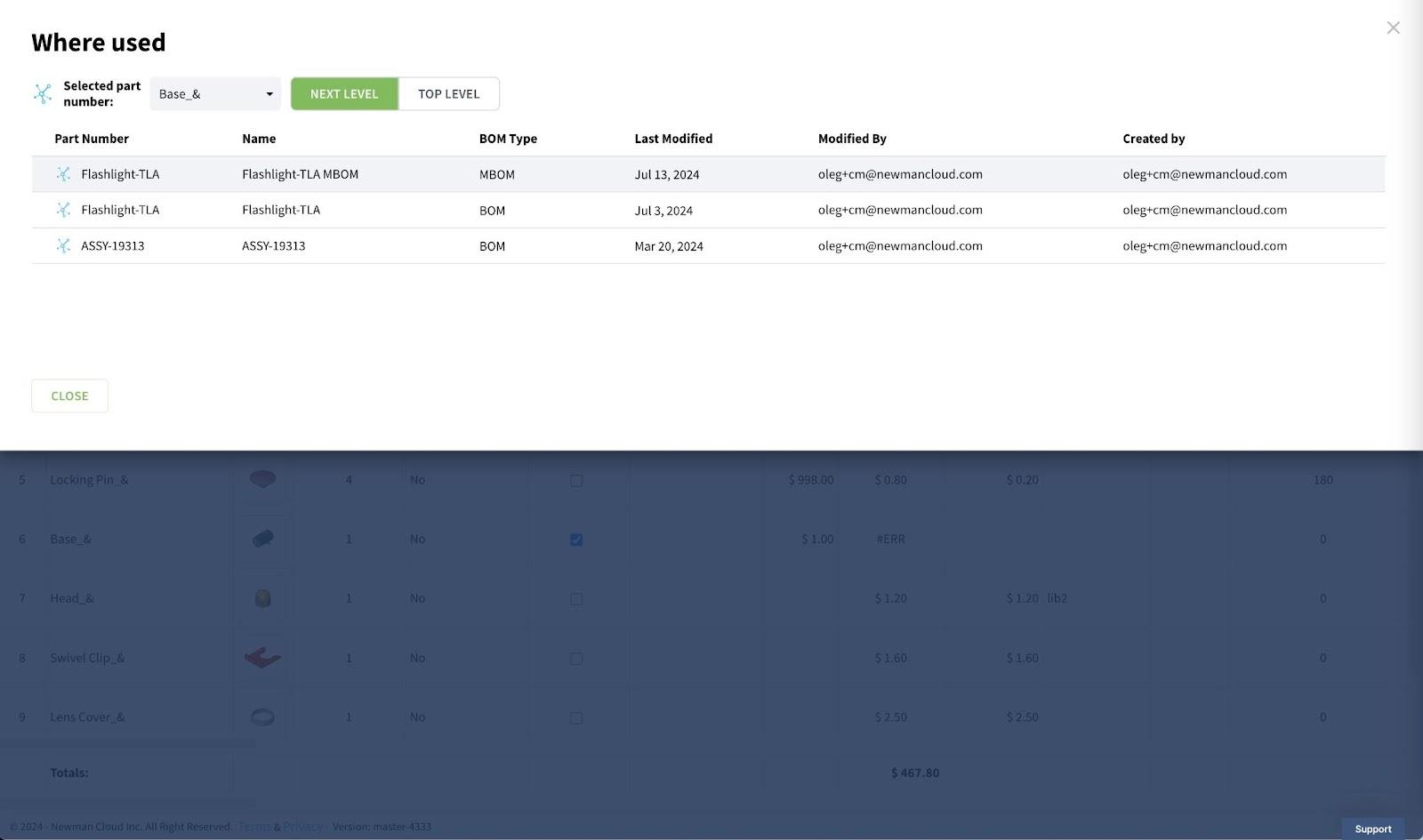

5.3 Where-Used Query and Navigation

The “where-used” query mechanism in OpenBOM has been adapted to support different BOM types.

Users can:

- View Multiple BOM Types: See where each item is used across various BOM types.

- Navigate to Specific BOM Types: Easily navigate to the relevant BOM type using the “where-used” command.

Practical Examples of BOM Types

The xBOM service supports a wide range of BOM types, each serving different purposes within the product lifecycle.

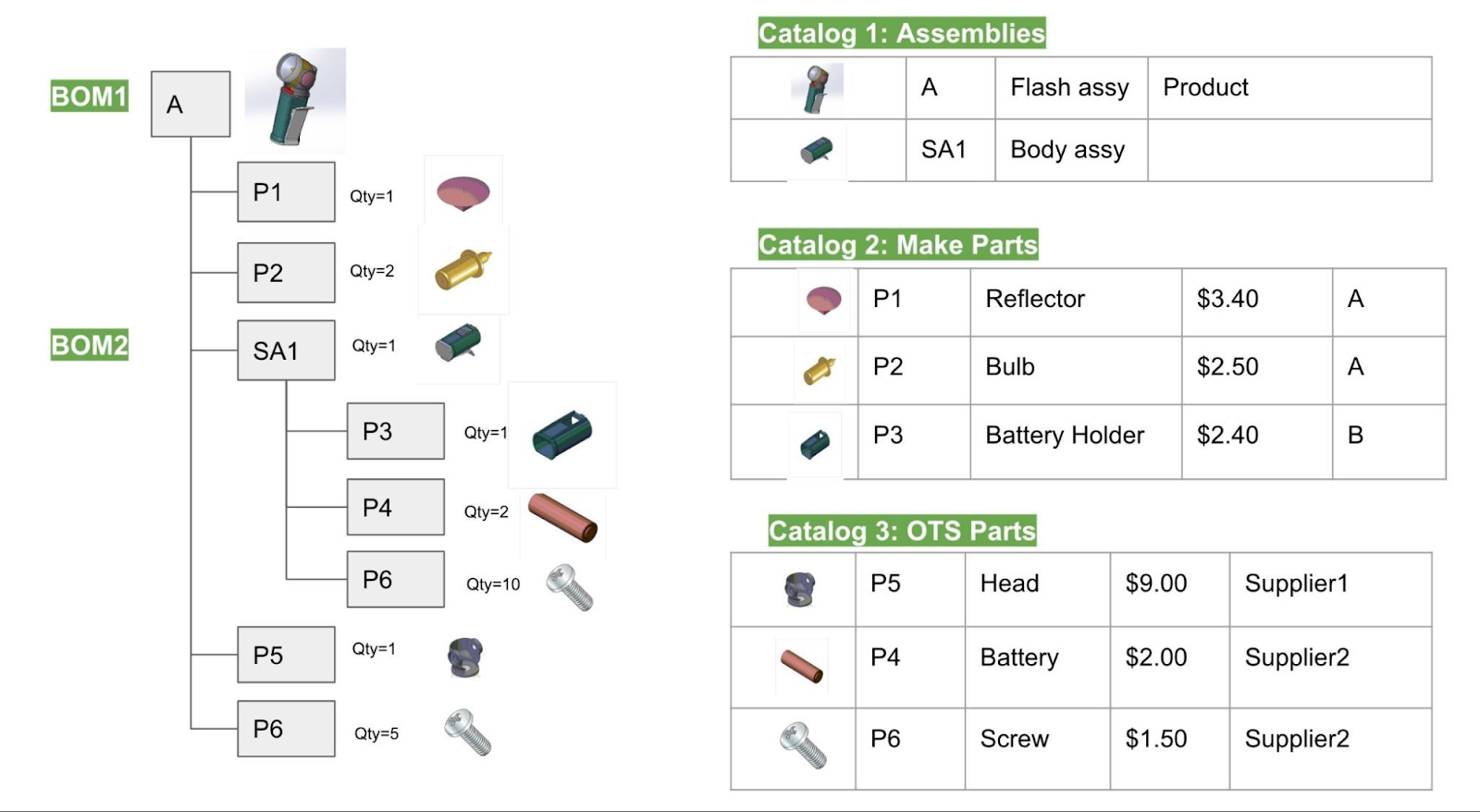

6.1 Simple BOM

A Simple BOM is the most basic type of BOM, listing all components needed to build a product. It includes essential information such as part numbers, descriptions, and quantities. The Simple BOM serves as the foundation for more complex BOM types.

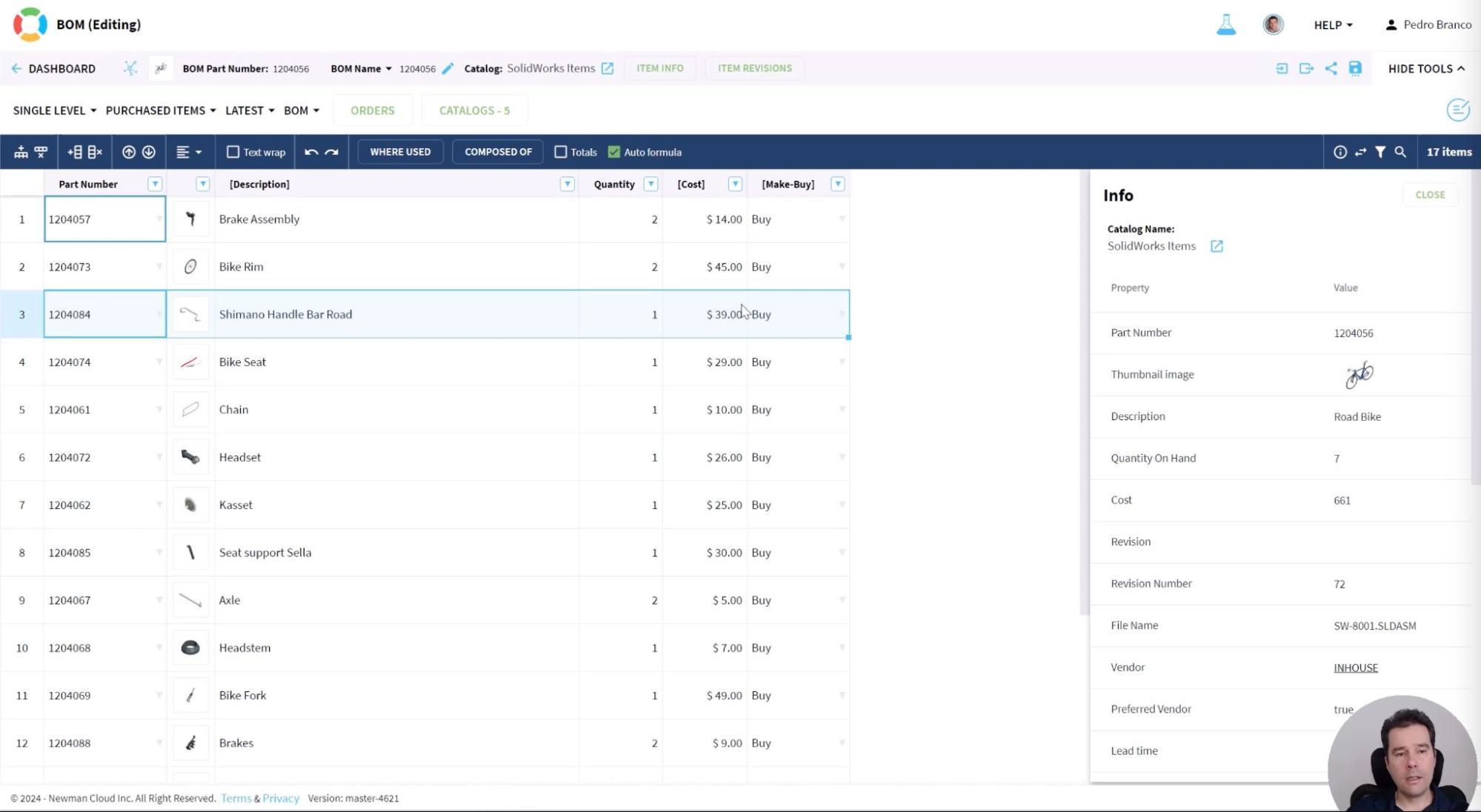

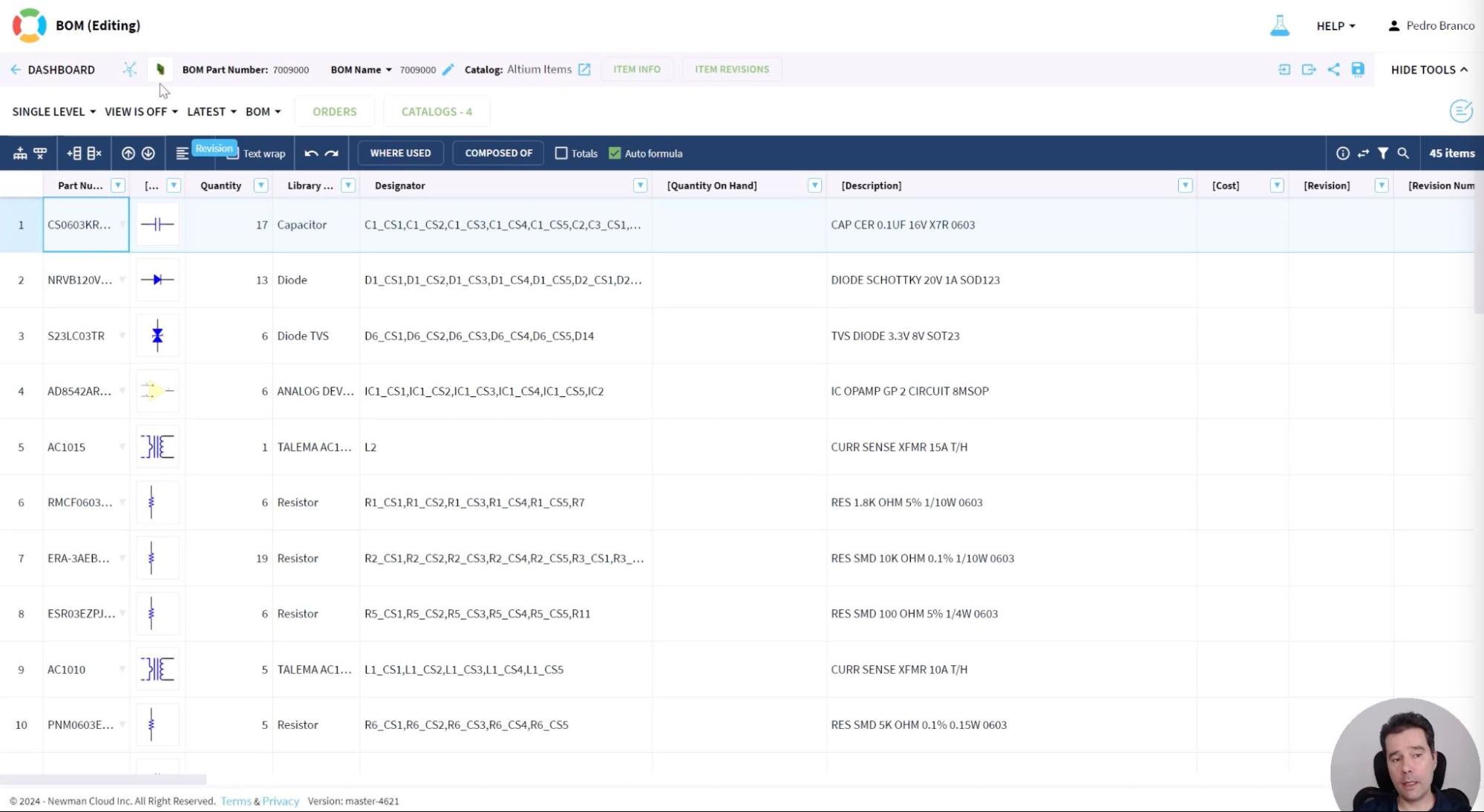

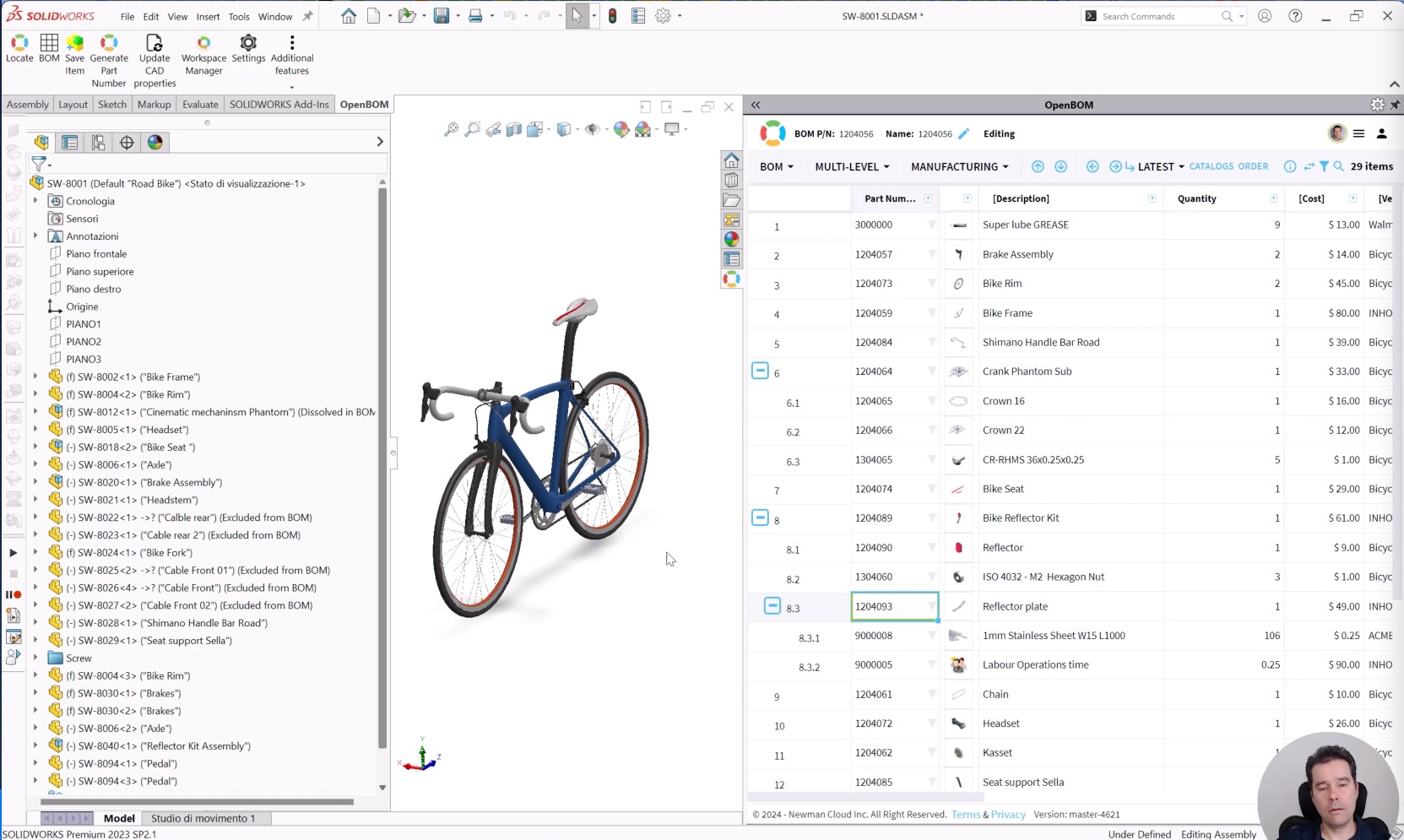

6.2 Engineering BOM (EBOM)

The Engineering BOM (EBOM) originates from the CAD system and reflects the design intent of the product. It includes all components, assemblies, and sub-assemblies as designed by the engineering team. The EBOM is crucial for ensuring that the product is built according to design specifications.

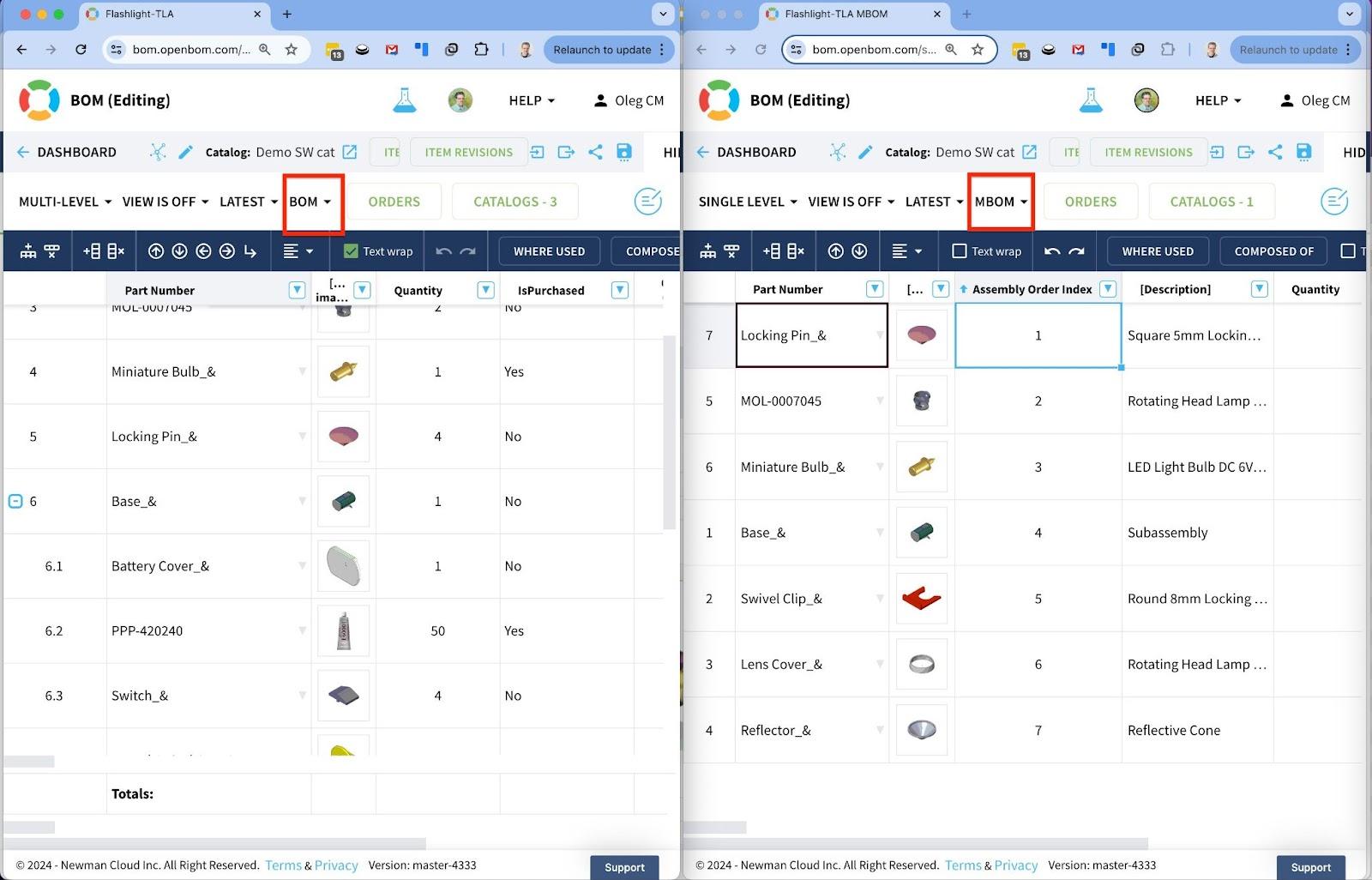

Screenshot

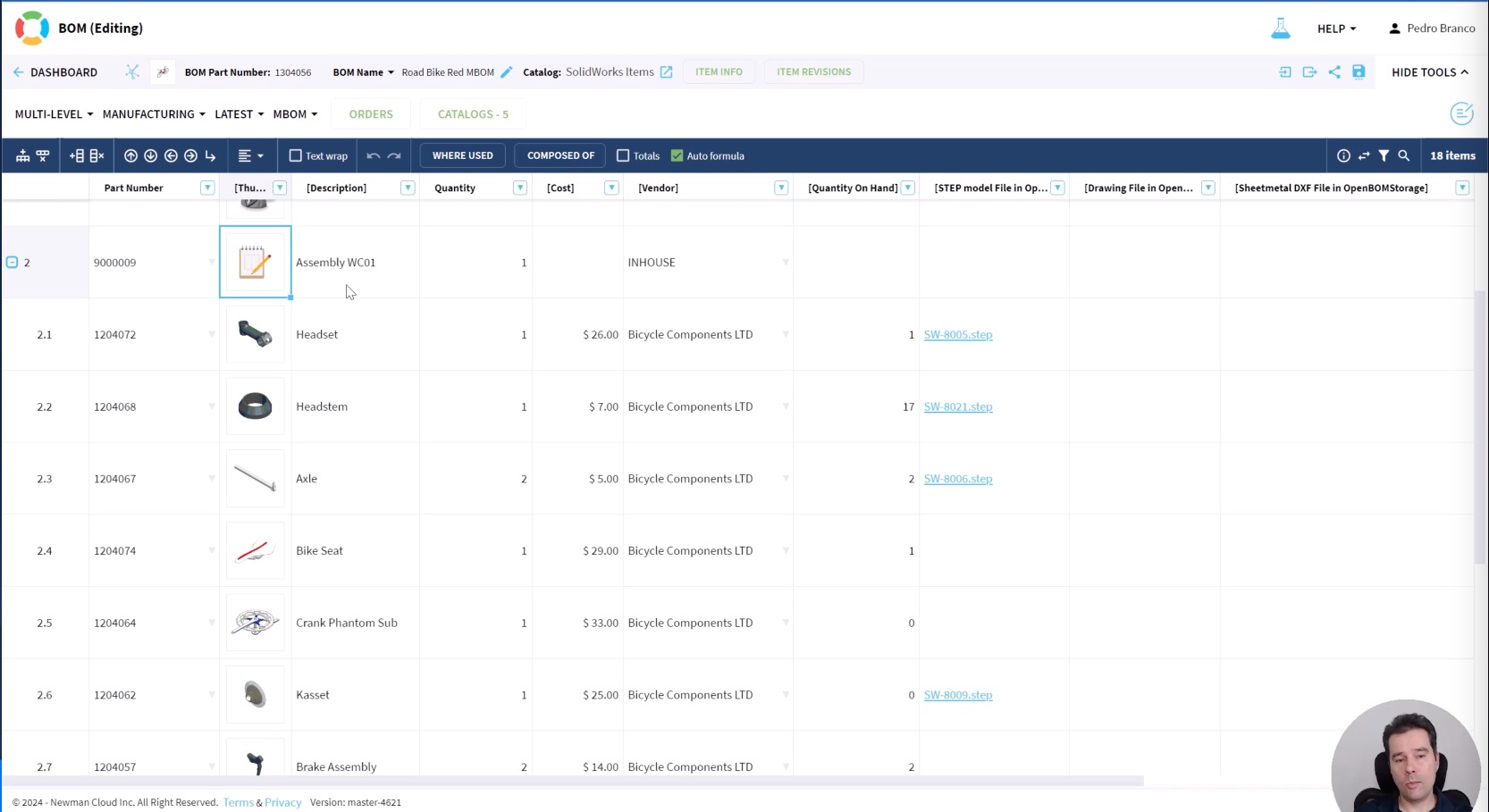

6.3 Manufacturing BOM (MBOM)

The Manufacturing BOM (MBOM) is organized to facilitate the production process. It includes detailed information about how and when parts should be assembled, including sequences, components, and workstations. The MBOM is essential for production planning and execution.

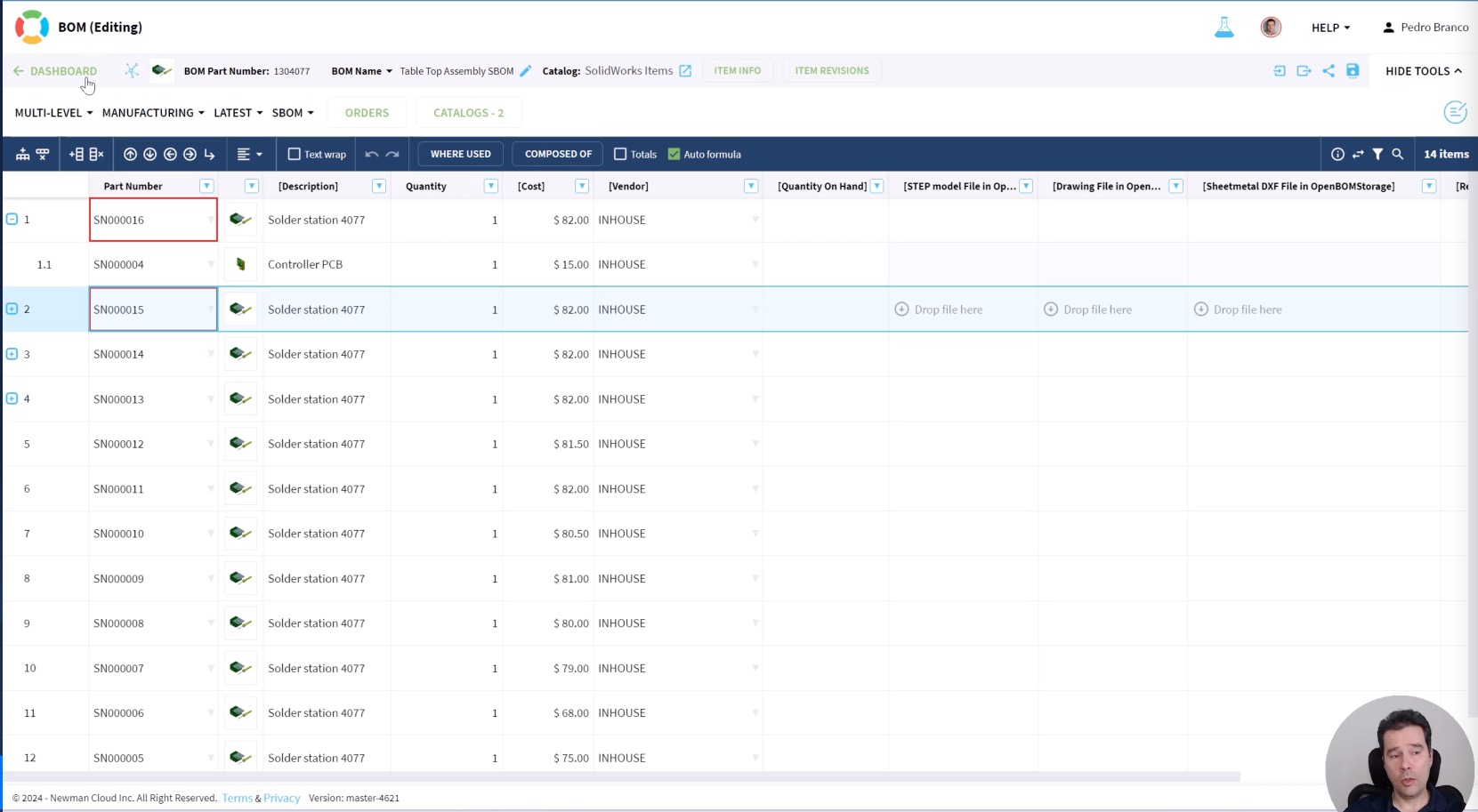

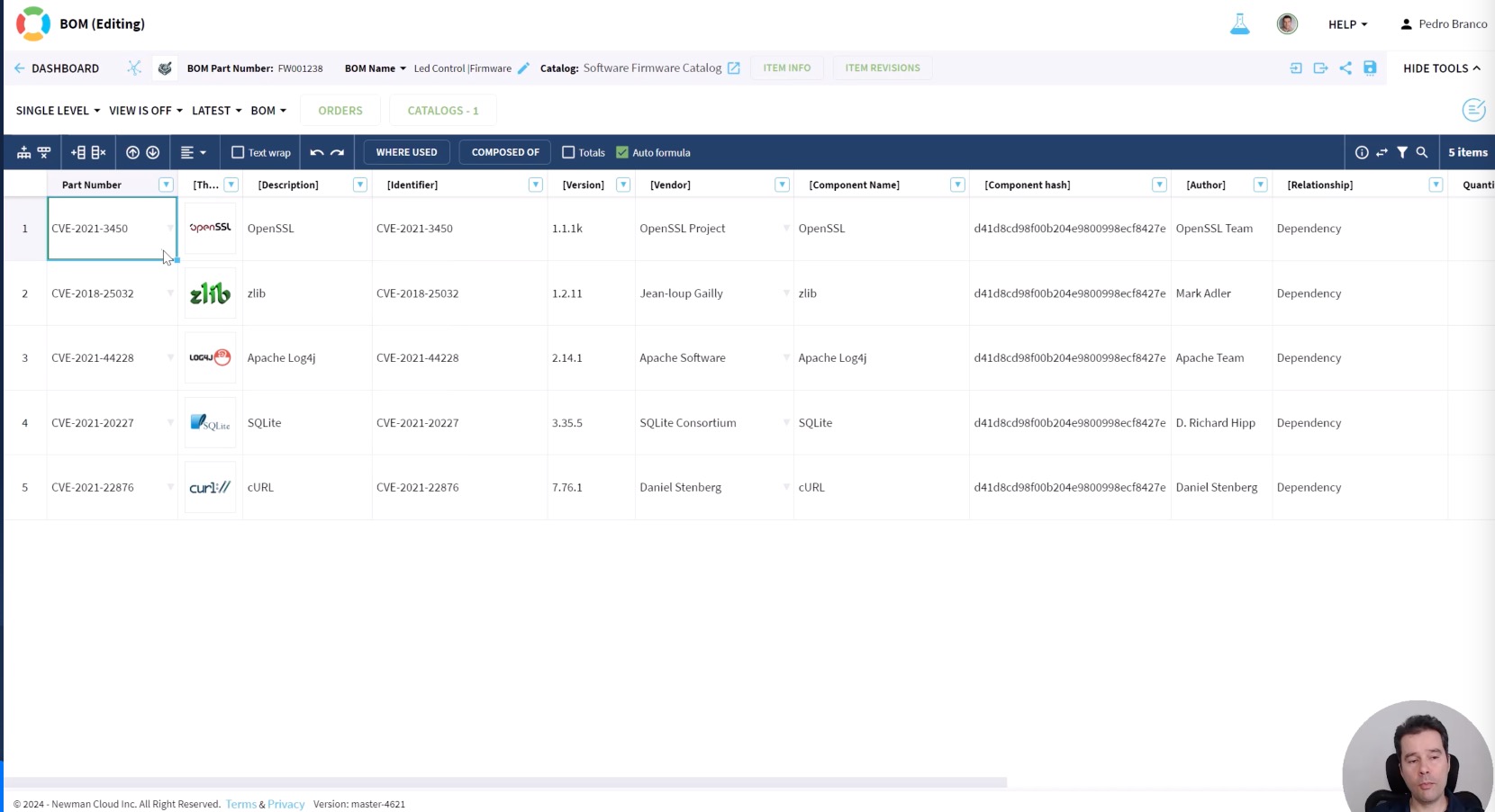

6.4 Support and Service BOM (SBOM)

The Support and Service BOM (SBOM) is designed for post-production support, including maintenance and repairs. It tracks serial numbers, spare parts, and service procedures, ensuring efficient after-sales support. The SBOM is vital for maintaining products in the field.

6.5 Functional BOM

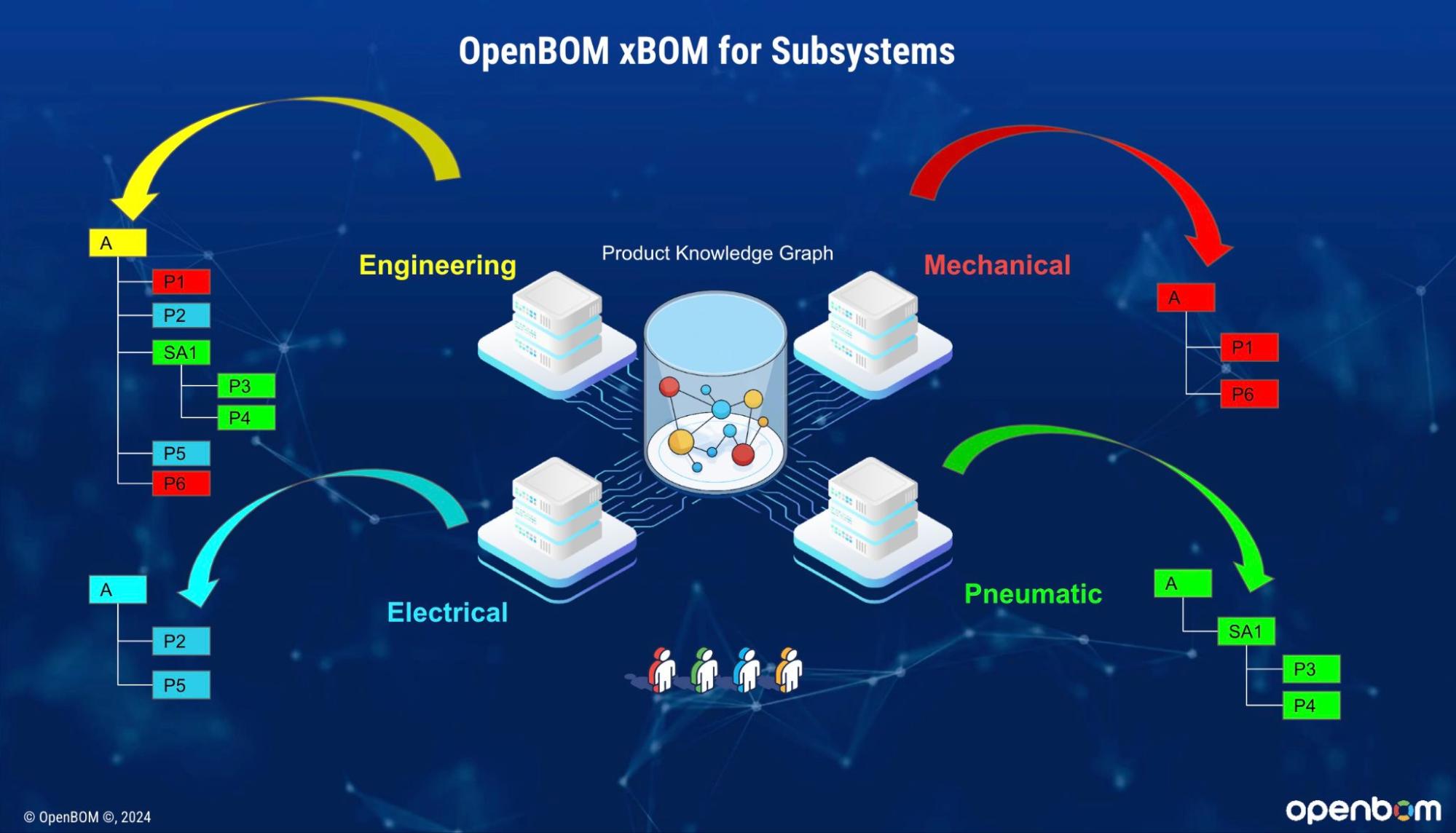

A Functional BOM focuses on specific subsystems of a product, such as the electrical or mechanical subsystems. This type of BOM is particularly useful for complex products with multiple interdependent subsystems. It allows for detailed management of each subsystem, facilitating better collaboration and integration.

Software BOM

Advanced Features and Future Enhancements

OpenBOM’s xBOM service is constantly evolving, with new features and enhancements planned for future releases.

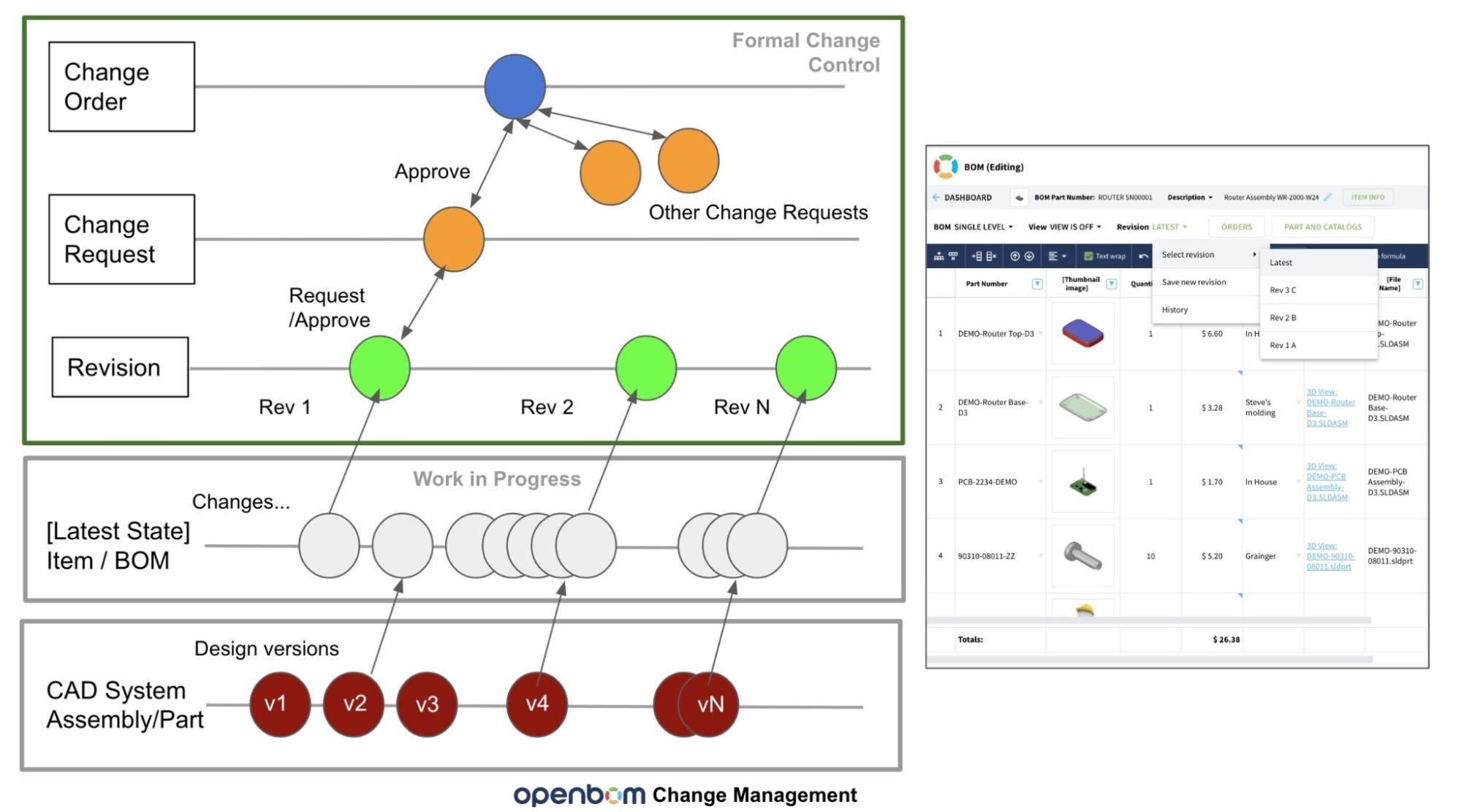

7.1 Revision Management and Change Control

Revision management and change control are critical functions within the xBOM service. These features ensure that every modification to an item or BOM is meticulously tracked, providing a clear history and maintaining data integrity.

- Item Revisions: When an item is revised, OpenBOM automatically creates revisions for all connected BOM types, ensuring consistency across the product lifecycle.

- Change Management: The xBOM service supports Engineering Change Orders (ECO) and other change processes, allowing users to manage changes efficiently.

7.2 Graph Navigation and Advanced BOM Comparison

Upcoming features will include:

- Advanced BOM Comparison: Tools for comparing different BOM types side-by-side, highlighting differences and facilitating better decision-making.

- Graph Navigation: Enhanced navigation through the product knowledge graph, allowing users to explore complex relationships within the BOM structure.

Using xBOM for Complex Subsystem Modeling and Cost Estimation

The xBOM service is not just about managing BOM types; it also provides powerful tools for modeling complex subsystems and estimating costs.

8.1 Subsystem Data Modeling

Modern products are increasingly complex, requiring robust data modeling capabilities to represent various subsystems, such as electrical, mechanical, and pneumatic systems.

The xBOM service allows users to:

- Create xBOM Types for Each Subsystem: Define xBOM types for different subsystems (e.g., mechanical, electrical).

- Build BOMs for Each Subsystem: Develop a BOM for each subsystem type, organizing the required items and their relationships.

- Integrate Subsystems: Use the same items across different xBOM representations to ensure consistency and accurate modeling of the overall product structure.

8.2 Cost Calculation and Rollups

Accurate cost estimation is critical for product design and planning. The xBOM service supports:

- Formula Support: Users can create formulas for cost rollups, calculating costs based on quantities and item costs from catalogs.

- Automated Updates: Changes in item costs within catalogs automatically update all xBOM-specific cost calculations, ensuring up-to-date cost assessments.

I recommend you to check the OpenBOM Cost Calculation Live Demo to learn more about how to manage formulas and rollup.

Unlocking the Digital Thread with xBOM

The digital thread is becoming increasingly important in manufacturing, providing a connected flow of data throughout the product lifecycle.

9.1 Digital Thread Architecture

The digital thread architecture supported by xBOM enables seamless integration across different systems and data points. Unlike traditional linear models, the digital thread is dynamic and adaptable, allowing companies to create and maintain connections between disparate systems like CAD, PLM, and ERP.

9.2 Enabling a Distributed Digital Thread

Data is a new oil of the modern digital environment. Therefore the way companies can manage information about their products and processes is critical for company success. That was the mantra of PLM and how it was defined 20-30 years ago when visionaries of engineering and manufacturing computer systems extended the principles of computer-aided design and manufacturing to support complex processes to develop highly configurable products.

But we are moving forward. The trends toward connectivity and connected products and what was called the “Internet of Things” pushed companies to the next level of connectivity. What is even more important is the switch towards selling services and not products. Think about selling “miles” instead of tiers, selling “hours of construction work” instead of selling construction equipment, and “hours of power generation” instead of buying turbines. The transformation is everywhere. You might think it applies only to large companies and you would be wrong. Think about the “service approach” everywhere. Think about companies selling “service to monitor the quality of agriculture” instead of selling drones spreading chemicals, “services to charge electrical vehicles” instead of selling chargers, etc.

I recommend you check out a very visionary article written by Michael E. Porter and James E. Heppelmann – “How Smart, Connected Products Are Transforming Competition“. In this seminal article, you can learn about the profound impact of information technology on product design, functionality, and competition. Traditional products, once composed solely of mechanical and electrical parts, have evolved into complex systems combining hardware, sensors, data storage, microprocessors, software, and connectivity. This evolution, driven by advances in processing power, miniaturization, and wireless connectivity, has revolutionized how products operate and interact with their environment, giving rise to “smart, connected products.”

These smart, connected products offer unprecedented opportunities for enhanced functionality, reliability, and efficiency, transcending traditional product boundaries and significantly altering value chains. Companies are compelled to rethink and revamp their internal processes to leverage these new capabilities, leading to a shift in how they create and capture value. As a result, industry structures are being reshaped, and companies face new competitive dynamics, including the need to redefine their strategic positioning and business models.

Porter and Heppelmann argue that smart, connected products fundamentally transform the nature of competition by introducing new strategic choices and operational implications. Companies must navigate this landscape by understanding the broader implications of these technologies, which extend beyond the products themselves to encompass new data management practices, customer relationships, and industry boundaries. This shift leads to the third wave of IT-driven competition, characterized by the integration of IT directly into products, thereby driving significant improvements in product functionality and performance, reshaping value chains, and creating new opportunities for competitive advantage.

At OpenBOM, we work with many innovative companies that are looking at how to organize their information to support processes in such a complex and connected world. The ugly truth behind all conversations about connected products is that you have somewhere a bunch of Excel spreadsheets, filled manually by people trying to organize information about engineering structures, purchase orders, suppliers, components, etc. Even if a company decides to use existing PLM software from mindshare PLM leaders, the product database is limited to a single company, and connectivity with others is supported by export/import Excels.

It brings up a question about what information and product lifecycle management infrastructure is needed to support the future of smart and connected products. And this is what we do at OpenBOM.

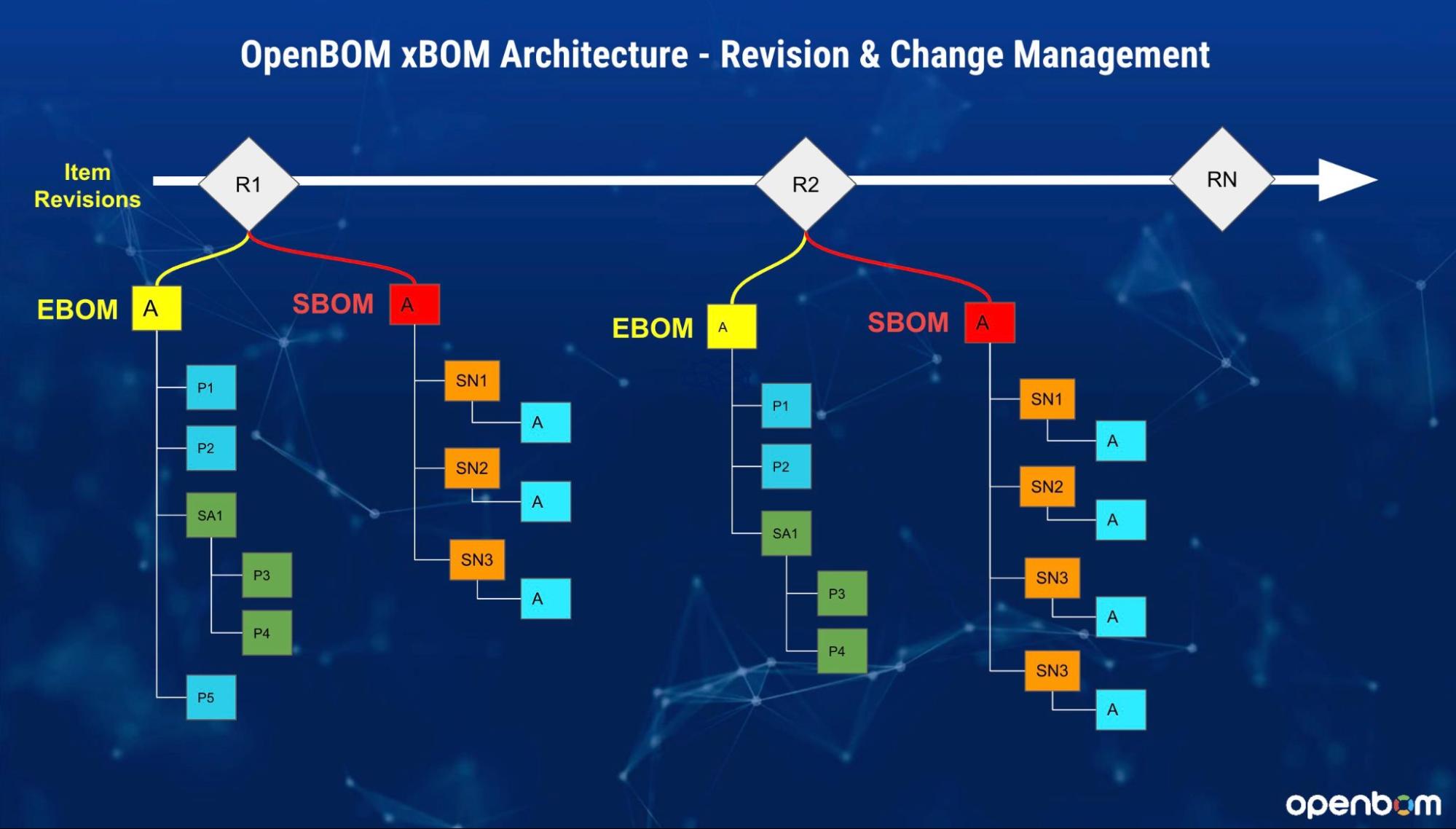

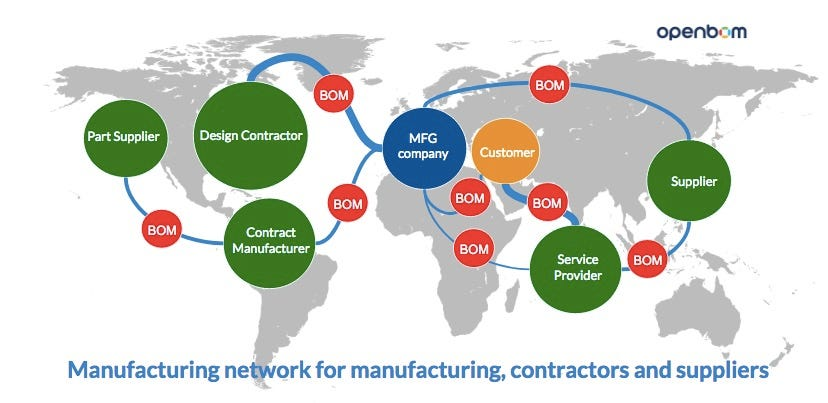

OpenBOM xBOM Architecture: Foundation for Distributed Data

OpenBOM’s multi-view xBOM architecture lays the groundwork for a distributed data environment that extends beyond the boundaries of a single company. Unlike traditional EBOM (Engineering Bill of Materials) and MBOM (Manufacturing Bill of Materials), which are typically confined to one organization, OpenBOM’s architecture enables the management of BOMs across multiple entities. For example, an EBOM might be managed by the original manufacturer, an MBOM by a contractor, and a customer’s as-maintained BOM by a service provider. This distributed data architecture, though seemingly futuristic, mirrors current practices where companies exchange large volumes of spreadsheets to manage BOMs across organizational boundaries.

The xBOM architecture facilitates seamless data sharing and collaboration by providing a mechanism to define a distributed digital thread of information. This is achieved through a multi-tenant environment that segments data structures while connecting them through a global product knowledge graph. This approach ensures that all stakeholders have access to the most up-to-date and accurate information, enhancing traceability, reducing errors, and improving overall efficiency.

OpenBOM xBOM Architecture: Enabling a Distributed Digital Thread

OpenBOM’s xBOM architecture is designed to support a distributed digital thread of information, essential for managing complex product life cycles in a multi-company environment. By segmenting data structures within a multi-tenant environment and connecting them via a global product knowledge graph, OpenBOM enables seamless integration and collaboration across different organizations. This architecture allows companies to maintain their data autonomy while ensuring interoperability and data consistency across the entire product lifecycle.

The distributed digital thread facilitated by OpenBOM provides several advantages. It enhances data accuracy and reduces the risk of errors by eliminating the need for manual data entry and spreadsheet exchanges. It also improves traceability, allowing stakeholders to track changes and updates throughout the product life cycle. Moreover, it supports real-time collaboration, enabling teams to work together more efficiently and make informed decisions based on the latest data.

Articles and Live Demo Links

- Coming Soon: Product Structures and BOM Types

- Introduction of OpenBOM xBOM Service

- Introducing xBOM Service: BOM Management Use Cases

- Press Release: OpenBOM Introduces Groundbreaking xBOM Feature, Simplifying Complex BOM and Digital Thread Management

- Empowering Smart Connected Products: OpenBOM’s xBOM Architecture for a Distributed Digital Thread

- OpenBOM Architecture for xBOM and Role-Based Access

- xBOM Video Demo: Create BOM Types and Managing EBOM, MBOM, and SBOM

- xBOM Video Demo: Managing Service and Maintenance BOM with Serial Numbers

- Product Lifecycle & Digital Twin: How Many xBOM Types Do We Need in an Organization?

- Using xBOM Service for Modeling and Cost Estimation of Complex Subsystems

- OpenBOM Live Demo for xBOM

- Unlocking the Digital Thread: How OpenBOM’s xBOM Services Stand Out

- Practical Guide and Examples of Different BOM Type Usage

Conclusion

OpenBOM’s xBOM service represents a significant advancement in product data management, offering a flexible, robust, and user-friendly framework for managing multiple product structures across different lifecycle stages. By leveraging the powerful graph-based data model and multi-view BOM architecture, xBOM provides users with the tools they need to streamline their operations, improve collaboration, and achieve greater efficiency in product development and maintenance.

Whether you’re managing a simple BOM, an Engineering BOM, a Manufacturing BOM, or a Service BOM, OpenBOM’s xBOM service ensures that all aspects of your product’s lifecycle are covered with precision and ease. With ongoing enhancements and a commitment to innovation, OpenBOM continues to lead the way in revolutionizing product data management.

Start a Trial: REGISTER FOR FREE to explore how OpenBOM’s xBOM service can transform your product lifecycle management processes.

Best regards,

Oleg Shilovitsky

CEO, OpenBOM