OpenBOM™ is a registered Trademark of Newman Cloud, Inc. | © 2022

- Home

- Training Courses

- OpenBOM Basics Course

- Registration & Settings

- Dashboard Walkthrough & Searches

- Creating BOMs from Excel

- Creating BOMs from CAD

- Creating BOMs Manually

- Preparing Catalogs

- Multi-Level & Flattened BOMs

- Exporting Reports

- Creating User-Defined Views & Filtering Information

- Real-Time Collaboration

- Revision & Change Management

- Managing Your Team

- OpenBOM Data Management Course

- OpenBOM Change Management Course

- End-to-End Design to Purchase Process

- Introduction

- 1. Install OpenBOM Add-In

- 2. Sign into OpenBOM

- 3. Edit Your Settings

- 4. Create a BOM Using the One-Click BOM

- 5. Create a Vendor List

- 6. Open Your CAD Items Catalog

- 7. Add Business Data to Your Items (Vendors and Costs)

- 8. Order Long-Lead Items

- 9. Mark a Purchase Order as “Received” in OpenBOM

- 10. Create an Order BOM

- 11. Create a Purchase Order

- 12. Export a Purchase Order

- OpenBOM CAD Integration Courses

- OpenBOM Design Course

- Premium Onboarding Experience

- OpenBOM Basics Course

- Getting Started

- Video Demos

- OpenBOM Basics

- Training Courses

- Part Number Management

- Import Data

- Design Projects

- New Product Development Process

- CAD Integrations

- Bill of Materials

- OpenBOM Community

- “Where Used” and Graph Navigation

- Flattened BOM Feature

- Generate PDFs (and More) from CAD

- Generate Part Numbers for CAD

- Create RFQs and POs

- Manage Revisions of Attached Files

- Export Data as a Zip

- OpenBOM YouTube Channel

- Administration

- Data Management

- Properties

- File Management

- Search & Filters

- BOM Types

- Creating BOMs

- BOM Compare Service

- Formulas, Calculations, & Rollups

- Organizing Data

- Custom Objects

- Design Projects (PDM)

- Using Templates

- Exporting Data

- User-Defined Views

- Team Views

- Collaborate & Share

- Production Planning & Inventory Control

- Change Management and Revision Control

- User Defined Commands

- xBOM Types

- Integrations

- Home

- Training Courses

- OpenBOM Basics Course

- Registration & Settings

- Dashboard Walkthrough & Searches

- Creating BOMs from Excel

- Creating BOMs from CAD

- Creating BOMs Manually

- Preparing Catalogs

- Multi-Level & Flattened BOMs

- Exporting Reports

- Creating User-Defined Views & Filtering Information

- Real-Time Collaboration

- Revision & Change Management

- Managing Your Team

- OpenBOM Data Management Course

- OpenBOM Change Management Course

- End-to-End Design to Purchase Process

- Introduction

- 1. Install OpenBOM Add-In

- 2. Sign into OpenBOM

- 3. Edit Your Settings

- 4. Create a BOM Using the One-Click BOM

- 5. Create a Vendor List

- 6. Open Your CAD Items Catalog

- 7. Add Business Data to Your Items (Vendors and Costs)

- 8. Order Long-Lead Items

- 9. Mark a Purchase Order as "Received" in OpenBOM

- 10. Create an Order BOM

- 11. Create a Purchase Order

- 12. Export a Purchase Order

- OpenBOM CAD Integration Courses

- OpenBOM Design Course

- Premium Onboarding Experience

- OpenBOM Basics Course

- Getting Started

- Video Demos

- OpenBOM Basics

- Training Courses

- Part Number Management

- Import Data

- Design Projects

- New Product Development Process

- CAD Integrations

- Bill of Materials

- OpenBOM Community

- "Where Used" and Graph Navigation

- Flattened BOM Feature

- Generate PDFs (and More) from CAD

- Generate Part Numbers for CAD

- Create RFQs and POs

- Manage Revisions of Attached Files

- Export Data as a Zip

- OpenBOM YouTube Channel

- Administration

- Data Management

- Properties

- File Management

- Search & Filters

- BOM Types

- Creating BOMs

- BOM Compare Service

- Formulas, Calculations, & Rollups

- Organizing Data

- Custom Objects

- Design Projects (PDM)

- Using Templates

- Exporting Data

- User-Defined Views

- Team Views

- Collaborate & Share

- Production Planning & Inventory Control

- Change Management and Revision Control

- User Defined Commands

- xBOM Types

- Integrations

Bill of Materials

Explore OpenBOM’s product data model and learn about different bill of materials (BOM) visualization types.

OpenBOM Product Model Overview

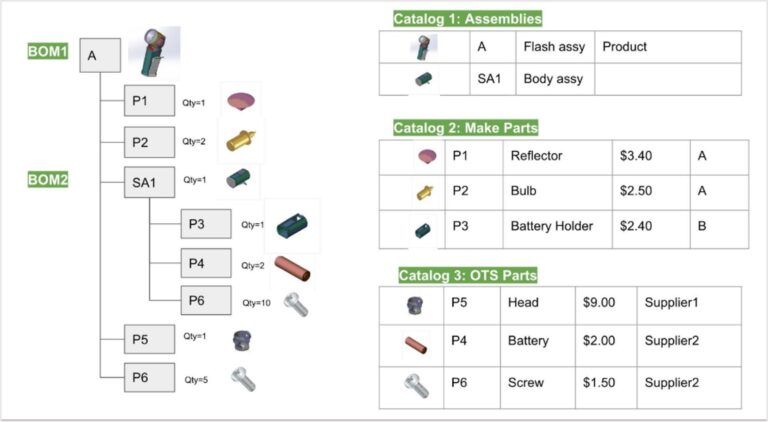

Items and Catalogs

OpenBOM controls all the information about different types of engineering and manufacturing items, such as a standard part, material, sub-assembly, or product. Anything can be an item in OpenBOM. Items are identified by unique part numbers and managed using catalogs.

Catalogs are used to store your standard items, engineering items, and products. They are also reusable. Every item you use in the bill of materials (BOMs) for every part, assembly, or sub-assembly must first be defined in the catalog. You can use it as a database to define your items for all BOMs.

OpenBOM catalogs allow you to preserve the history of changes in the catalog and create item revisions associated with the part number.

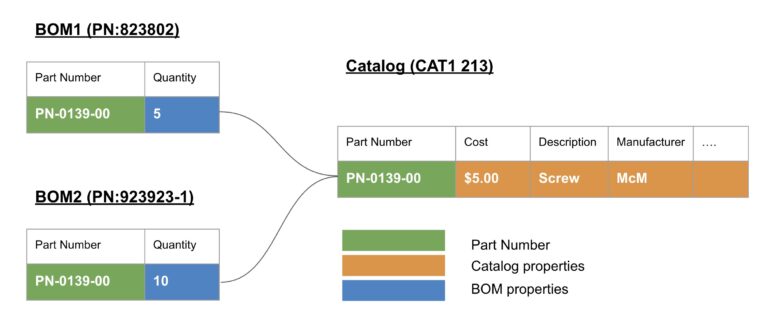

Part Numbers

Part numbers are key to data management as they support the uniqueness and traceability of data. At OpenBOM, part numbers are used as the primary identifier for each item in its system.

OpenBOM offers a flexible alternative to traditional part numbering systems, as you can incorporate characteristics from both non-intelligent and intelligent part numbers. You can use a simple combination of prefixes and numbers (non-intelligent) or implement a more complex schema (intelligent).

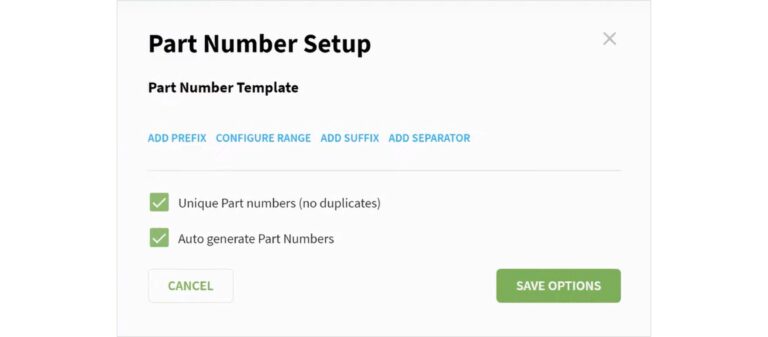

Every record in the OpenBOM catalog is associated with a part number, which becomes a unique identifier for your parts and assemblies. The OpenBOM catalog allows you to automatically generate part numbers and maintain their uniqueness.

Part numbers create parent-child relationships in BOMs. This term refers to each pair of assembly and sub-assembly that forms a type of relationship in which a higher level is called a parent and a lower level is called a child. These structures can be built top-down or bottom-up, without worrying whether the upper-level assembly or sub-assembly was created first.

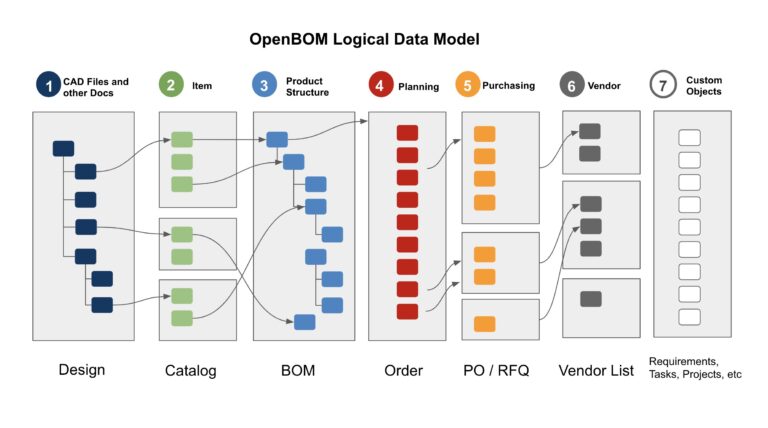

Product Structure: Hierarchical Relationships

Items and the product structure provide an abstraction model that efficiently manages the data for any product, simplifying the overall management process.

A product structure represents a full definition of the product with all items organized hierarchically as assemblies, sub-assemblies, and parts. These hierarchical relationships are efficiently managed by creating a graph structure between items using part numbers and all BOMs. By creating items and BOMs, a virtual product structure is created in OpenBOM databases, defining relationships between three objects.

BOMs

A BOM represents the full set of information about a product, grouping all assemblies, parts, and materials with the corresponding quantities and connected documents. It is also known as a product structure that contains important components (parts, materials, and assemblies) required to manufacture a final product.

This structure is usually made up of assembly and sub-assemblies (sub and intermediate) and components (parts and materials). It also includes details about all the necessary parts and their quantity.

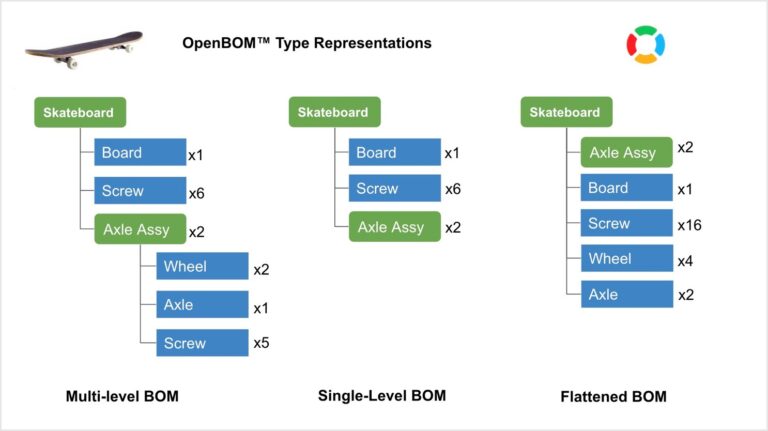

BOM Visualization Types

OpenBOM allows you to create and manage any type of BOMs from very simple part lists to very complex multi-disciplinary structures with a diverse set of properties at each level. These BOM types give you a full range of flexibility when it comes to the definition of simple part lists and complex structures.

There are three fundamental BOM types: multi-level BOM, single-level BOM, and flattened BOM. These BOM types are three representations of the same product structure.

Multi-Level BOM

A multi-level BOM is the most comprehensive structure in OpenBOM. It is a structure that OpenBOM creates by visualizing single-level BOMs and parent-child relationships. It allows you to explore and edit all structure elements (items) with ease, including the ability to perform operations like shifting from left to right.

Single-level BOM

A single-level BOM is the simplest of the OpenBOM data model, making it the easiest to edit. It is a flat list of items with a set of attributes (properties) and a mandatory part number. A list of properties can be custom, so you can add any properties.

Editing a single-level BOM streamlines your tasks by allowing you to modify a simple list within a complex product structure. It is especially useful when defining a specific level in your product hierarchy.

Flattened BOM

A flattened BOM is the most interesting visualization type, which gives you a way to summarize a structure in a flat list by roll-up of item quantities across multiple levels.

Think of a flattened BOM as a list of all the parts from all levels of your BOM together with the aggregate total quantities for each part shown. It’s a great way to see the quantities of ALL parts (no matter what level of the BOM they appear in) with their summed quantities.

Reference-Instance Model

Although OpenBOM looks and feels like Excel, it is not Excel. The foundation of the OpenBOM product structure is a reference-instance data model that manages two major information objects – items and BOMs.

In a nutshell, the reference-instance model is an abstraction model which allows you to model product structure information combined from references of parts (abstract objects) and their instances (specific instances in a BOM).

In the picture below, you can see that wheel, board, axle, and screw are examples of references, while “Wheel 1”, “Wheel 2”, “Board 1”, etc are examples of instances.

OpenBOM’s model combines flexibility and simplicity, offering real-time and instance-level accessibility. This unique design allows you to define and modify BOMs and property definitions on the go, resembling the functionality of Excel spreadsheets. At the same time, OpenBOM ensures data is structured so that it can be easily reused, enhancing efficiency, and streamlining your workflow.

If you’d like to learn more about BOMs, watch the video below.